Edge banding machine cutters are indispensable tools in woodworking, and they directly affect the quality and efficiency of edge banding. There are many types of edge banding machine cutters in the market. The following are 6 commonly used edge banding machine cutters for your reference.

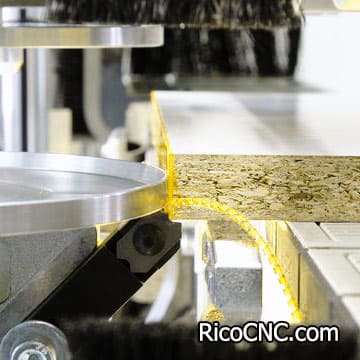

1. PCD Pre-milling cutter

Pre-milling cutter is one of the core tools in edge banding, mainly used for pre-milling the edge of the board before edge banding. By milling, burrs, ripples, or processing residues on the edge of the wooden board are removed to form a smooth and flat bonding surface, which improves the fit between the edge banding and the board. Ensure that the edge banding is tightly bonded to the board to avoid problems such as warping, cracking, or exposed glue lines.

The pre-milling cutter head uses a left and right rotation, double-knife structure to remove 20 wires (0.2mm) of burrs and cracks on the edge of the panel to ensure the flatness of the bonding surface of the edge banding.

There are generally two types of diamond pre-milling cutter:

Welded PCD pre-milling cutter: the diamond blade is welded to the cutter body, and the blade cannot be replaced

Disposable diamond pre-mill cutter: the diamond blade is replaceable, and the maintenance cost is reduced by 30%

You can choose the matching pre-milling tool according to the brand and model of the edge banding machine.

For example:

common dimension for Homag : 100X43.2X30 Z=3+3 2001804330 R and 2001804320 L

common dimension for Biesse: Pre-Mill Cutter CSEN350086 80x30xH65 Z3+3

common dimension for SCM: Diamond Jointing Cutter 07L0115304L 07L0150829G 80X56X30 Z2+2

2. Saw blades

Edgebander saw blades are used to cut and trim edge banding. The high-speed rotating sharp teeth accurately cut off the excess edge banding belt on the edge of the board to ensure that the edge banding and the board are seamlessly connected while providing a flat base surface for subsequent pressing, chamfering, and other processes.

The saw blade cuts the edge banding to the preset length and achieves high-precision cutting through the high-frequency and high-speed motor drive. The cross-section is flat and smooth, avoiding burrs or edge collapse.

To meet different edge banding needs, it is divided into end trim saw blades and trimming edge saw blades. End trim saw blades can cut off the excess edge banding at both ends of the board. The double saw blades work together (rotating in opposite directions) to accurately cut off the front and rear excess of the edge banding. At the same time, the left and right alternating tooth design reduces the edge collapse rate. The trimming saw blade is used to trim the upper and lower edges of the edge banding strip.

Includes carbide saw blades and diamond saw blades:

Carbide saw blades: cost-effective, suitable for routine production, but need regular grinding (such as the German Umicore welding blade repair mentioned on page 4).

Diamond saw blades: higher hardness, long life, suitable for high-load processing (such as metal edge banding or mass production), but the cost is higher.

Different brands have specific requirements for saw blade size (such as outer diameter, and inner hole), which need to be strictly matched, so pay attention when purchasing.

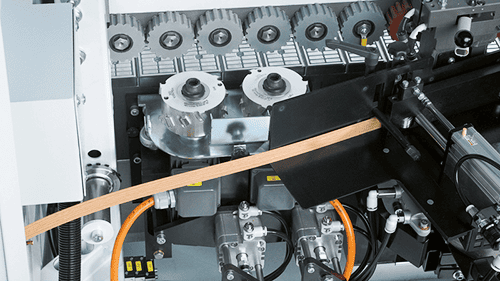

3. Rough trimming cutters

The edge banding machine rough trimming cutter is mainly used to quickly remove excess material on the upper and lower surfaces of the edge banding strip, laying the foundation for the subsequent high-precision processing of the fine trimming knife. Its core function is to make the edge banding strip initially flat through rough processing with a large amount of cutting while reserving a reasonable margin for the fine trimming process to ensure that the final edge banding effect is beautiful and flawless.

The rough trimming cutter is designed as a flat knife (the blade is straight without curvature), and it can quickly cut the upper and lower excess parts of the edge banding through high-speed rotation. For example, when processing an 18mm panel, the width of the edge banding is usually 22mm. The rough trimming cutter can cut off about 1mm of margin on both sides, greatly reducing the processing burden of the fine trimming cutter. The cutting amount is large (usually 0.5mm margin is reserved for the fine trimming knife to process), which is suitable for preliminary trimming of the flatness of the plate edge.

It is usually designed with multiple teeth, and the common structure is 4-6 teeth (such as the KDT roughing cutter has 4 teeth, and the Nanxing type has 6 teeth). The multi-tooth distribution balances the cutting force and improves efficiency. It is made of carbide or PCD material, has strong wear resistance, and can withstand high-cutting forces.

Common size:

4. Fine trimming cutter

The edge banding machine fine trimming cutter is mainly used for fine finishing after the edge banding is attached. After the rough trimming knife completes the basic cutting, the finishing knife will perform arc chamfering or fine trimming to avoid excessive tool wear or uneven edge banding caused by direct finishing. It completes the last step of fine processing in the edge banding process, ensuring that the edge banding effect is free of burrs and residues, and achieving edge processing of complex arcs or special shapes.

After the rough trimming cutter removes most of the excess material, the fine trimming cutter fine-tunes the upper and lower edges of the edge banding strip, with a very small amount of cutting (usually leaving about 0.05mm margin), ensuring that the edge banding strip fits seamlessly with the side of the board.

The edge of the edge banding strip is trimmed to a smooth arc through the R-shaped blade (arc design), which improves the touch and visual effects, especially suitable for the waterproof, heat-resistant edge banding requirements of high-end furniture and special edge banding.

The fine and rough trimming cutters have a clear division of labor in the edge banding process:

Roughing trimming cutter: quickly cut off the excess parts of the upper and lower edge banding, with a large amount of cutting (about 0.5mm margin), providing a basis for finishing.

Fine trimming knife: complete the "finishing" work based on rough trimming, and achieve the final beautiful effect through high-precision cutting. Both are indispensable.

5. Scraper blade

The edge banding scraper is a key tool used for fine trimming of the edge banding in the edge banding process. It is used to scrape off excess hot melt glue, wood chips, or burrs at the joints between the edge banding and the board to avoid glue line exposure or uneven surface. The edge banding surface is made flat and smooth. The chamfer design (such as a V-shaped groove) makes the edge of the edge banding form a rounded transition, enhancing the visual beauty and touch of the furniture.

The scraper and fine finishing cutter work together: after the finishing knife completes the edge curvature forming, the scraper blade further removes the remaining rotation knife marks to ensure that there are no wavy lines or scratches on the edge banding surface, thereby improving the edge banding quality.

Right-angle scraper: suitable for flat finishing of standard edge banding.

Bevel/rounded scraper: suitable for special-shaped edge banding or special chamfering requirements.

6. Tracking knife

An edge banding machine tracking knife (also called a contour tracking knife) is a core component used to trim the edges and corners of the board. By dynamically adjusting the tool path, the four corners of the board after edge banding are milled into a smooth R arc shape, improving the aesthetics and functionality of the edge banding process. It is Suitable for edge banding and trimming of non-straight edges such as arcs and waves, solving complex shape problems that traditional linear tools cannot handle.

Corner trimming: Milling is performed on the four corners of the board after edge banding to eliminate sharp corners or burrs, forming a uniform R arc (commonly R1.5-R3.5), enhancing the visual beauty and safety of furniture.

Dynamic tracking: Track the shape of the board (such as arcs and special-shaped edges) in real-time through sensors or mechanical templates, automatically adjust the tool path, and ensure that edges of different thicknesses and curvatures can be accurately processed.

Eliminate processing defects: Solve the ripples or jagged marks caused by non-linear motion during edge banding, making the transition of corners smoother.

Common size: 70×16×H16×3T R2.5

High-quality edge banding machine cutters can ensure precise cutting, and avoid uneven edges or burrs, thus improving the appearance quality of wood panels, and improving production efficiency and stability. Suitable tools can ensure that the edge band is firmly bonded to the substrate, avoiding the problem of loose edge banding due to tool wear or unsuitable tools.

Using efficient and durable tools can reduce the need for frequent replacement and maintenance, thereby reducing production costs and improving cost-effectiveness per unit output. RicoCNC provides different sizes and types of high-quality replacement cutters for different edge banders brands, such as Biesse (Akron, Jade,Polymac, Stream), SCM (Stefani, Idimatic, IDM), Fravol, IMA, Bi-matic, Cehisa, Hebrock Brandt, HolzHer, Homag, Genisis , KTD, Nanxing and many others. Welcome to contact us for more information!

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665