Difference between solid carbide and Tungsten steel

Tungsten Steel contains about 18% tungsten alloy steel.

Tungsten steel belongs to solid carbide, also known as tungsten-titanium alloy.

Hardness is 10K Vickers, second only to diamonds.

For this reason, tungsten steel products are commonly found in tungsten steel watches, which are not easily worn.

They are commonly used on lathe tools, drill bits, glass cutter heads, tile cutters.

They are hard to avoid annealing, but crisp.

Tungsten steel is a part of solid carbide, but solid carbide is not necessarily tungsten steel.

Now customers in Taiwan and Southeast Asian countries like to use the term tungsten steel.

If we talk deeply with them, we will find that most of them refer to the solid carbide...

Tungsten steel is made by adding tungsten iron as raw material of tungsten in steelmaking process, also called high-speed steel or tool steel.

The tungsten content is generally 15-25%; and the solid carbide is sintered by a powder metallurgy process with tungsten carbide as the main body and cobalt or other bonding metal,

and the tungsten content is generally above 80%.

Simply put, all the alloy whose hardness goes beyond HRC65 can be called solid carbide.

Tungsten steel is only a kind of solid carbide with a hardness between 85 and 92 HRC,

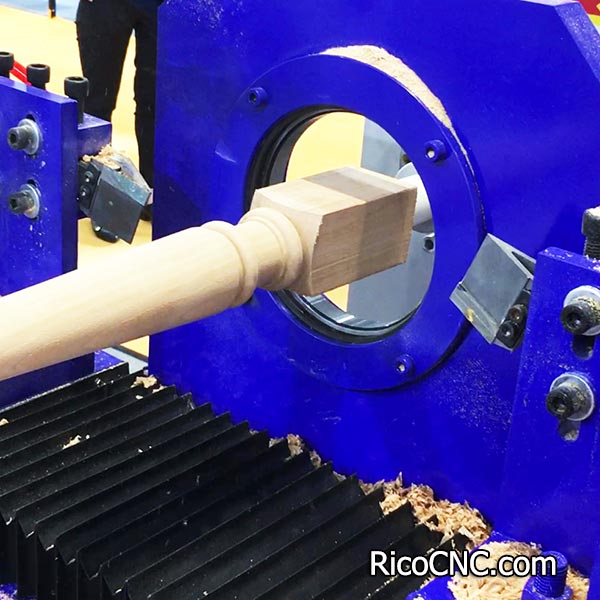

which is often used to make CNC router bits.

If you are looking for tungsten and solid carbide cutters, welcome to contact RicoCNC.

RicoCNC also supplies a range of CNC spare parts, woodworking machine tools,

metal milling machine accessories, EDM machine consumables, welcome your inquiry.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665