Edge banding machines are mainly used to band the edges of boards and are widely used in panel furniture manufacturing, greatly improving production efficiency. For example, a fully automatic edge bander can process 20 meters of boards per minute, which is dozens of times faster than manual work, and can also adapt to the processing of different materials and special-shaped boards. Whether for cabinet making, wardrobe making, or custom furniture, edge banding machines are woodworking machines that ensure the product is beautiful, durable, and efficiently produced.

There are many brands of edge banding machines on the market, among which Biesse brand located in Italy, Europe, is deeply loved by furniture manufacturers. Biesse Group is a is a global leader in the technology for processing wood, glass, stone, plastic, and metal. Biesse is Founded in Pesaro in 1969, by Giancarlo Selci. Biesse edgebander occupies a very high market position in the woodworking field.

Biesse edgebander reviews:

Biesse edgebanding machine product line is complete, divided into single-sided and double-sided edgebanding machines,

Single-sided linear edgebanders include the following models:

Biesse Akron 1100, Biesse Jade 200, Biesse Akron 1300, Biesse Akron 1400, Biesse Stream A Smart, Biesse Stream A, Biesse Stream B, Biesse Stream Edge Pro, Biesse Stream B MDS 1.1

Double-sided edgebanders and squaring and edgebanding machines:

Biesse Stream C

The Biesse AKRON series is designed for mass production, equipped with a pneumatic system and intelligent parameter adjustment function, which greatly improves production efficiency.

The Biesse JADE series is designed for small and medium-sized customized production. It adopts Rotax electric spindle technology, supports 18m/min high-speed processing, and is equipped with an automatic adjustment pre-milling device and temperature-controlled glue coating system. It is suitable for customized furniture, cabinet door panels, and other fields that require high precision and flexibility.

Biesse Stream series integrates intelligent tracking and polishing modules, is suitable for high-precision edge banding, supports EVA, PUR, and other glue processes。

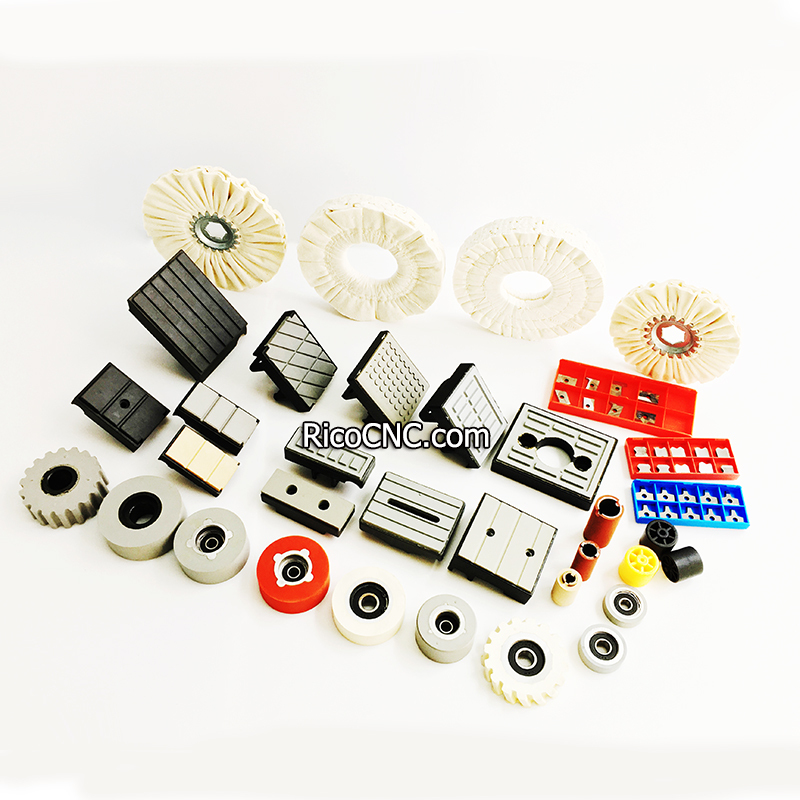

To ensure the efficient operation of the edge banding machine, daily maintenance of edgebander is essential, and high-quality accessories are the basis of maintenance. The following are the common parts of Biesse edge banding machines summarized by RicoCNC:

1.Rubber Pressure Roller

The rubber rollers are mainly used to apply stable pressure to the board during the edge banding process, to ensure that the edge banding fits tightly with the edge of the board, and to prevent the edge banding from warping or shifting when the glue is not dry.

Commonly used rubber wheels for Biesse edge bander:

E1422E0005 Pressure Wheel with Bearing 608 D60x8x24 Roller

E1422E0033 Red Heat-resistant Wheels 60x8x24 Roller

2. Chain Track Pads

The edge banding machine chain track pads (also known as the conveyor chain bads) is a block-shaped crawler component equipped on the fully automatic edge banding machine. It is mainly responsible for fixing and conveying the plate to ensure the stable movement of the workpiece and maintain processing accuracy during the edge banding process.

Common chain block models for Biesse

3.Cloth Buffing Wheel:

Use high-speed rotating cotton or cloth wheels to physically rub the edge surface to remove burrs, glue marks, and tiny knife marks, ultimately achieving a seamless connection and a beautiful effect between the edge material and the board.

150x50x20 Polishing Wheels for Biesse Akron Edgebander

N3405N0002 (0000107048A) Buffing Wheels D150x19x10mm

E3419E0001 D150x55x20MM Circles Fabric Polishing Buffing Wheel

4.Pre-milling cutter

The pre-milling cutter is mainly used to pre-process the edge of the board before edge banding to remove burrs, protrusions, or irregular parts, and provide a flat base surface for the subsequent high-quality bonding of the edge banding.

5. Rough trimming knife

The rough trimming knife is used to remove excess material on and below the edge banding strip to prepare for the work of the fine trimming knife.

6.Fine finishing cutter

The finishing knife is used after rough trimming. After the rough trimming knife completes the basic cutting, the finishing knife will perform arc chamfering or fine trimming to avoid excessive tool wear or uneven edge sealing caused by direct finishing.

7. Edge banding machine scraper

Scraper away excess hot melt glue, wood chips, or burrs at the joint between the edge banding tape and the board to avoid exposed glue lines or uneven surfaces.

Biesse edge banding machine blades come in many different sizes and shapes:

Biesse egebander knives:

Biesse N3402N0054 Wirutex D01535 Radius Knives

20 X 16.2 R=2 BUP 8210.020.000 Edge Scraper Insert Knives

BIESSE E3401E0117 Triangle Glue Scrape Knife

Carbide Insert N3402A0040

N3402N0082 N3402N0083 Multiprofile Carbide Insert Knife For Biesse Stream

Edge Scraper with Anti-bleaching Profile R=2 3402A0126

8. Saw Blade

Edge banding machine saw blade: The edge banding machine saw blade is used to cut and trim the edge banding to ensure a seamless connection between the edge banding and the board.

9. Panel Support Beam Roller

Edge banding machine edge wheel: Mainly used to support the board and ensure its stable and accurate transportation, prevent the board from shifting or sliding during the edge banding process, and ensure processing accuracy and efficiency

25x3x24mm Panel Support Beam Roller for Biesse Akron Roxyl Edgebanders

10. End Trim wheel

E1422E0009 D34 Rubberized Wheel with Bearing Edgebander End Trim Track Roller

34x8x10mm Grey End Trim Track Roller for Biesse Edgebander Trimming Unit

11. Rubber feed roller

Rubber Feed Roller E1122E0003 for Biesse

Other parts for Biesse egebander:

Biesse E1422E0036 Pusher Roller for Artech Akron

E1122E0004 Needle Roller for Biesse Edgebander

Copper Sleeve K1010K0004 for Biesse Edgebanders FT2 ATC Machines

Regular maintenance and replacement of worn parts can reduce the loss of the core components of the edge banding machine. Stocking some commonly used parts can reduce downtime, ensure the normal operation of the equipment, guarantee production efficiency, and extend the life of the machine.

RicoCNC carries a wide range of Biesse edgebander spare parts,sufficient stock,fast delivery to all over the world. Welcome to contact us!!

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665