What is pre-milling in edgebanding?

In the field of panel furniture and woodworking manufacturing, edgebander pre-milling has become a key process to improve edge banding quality and production efficiency. Premill refers to the fine processing of the edge of the board by a high-speed rotating milling cutter (diamond pre-milling cutter head) before the edge banding operation to remove defects such as burrs, ripples, and unevenness, and provide a flat and smooth base surface for the subsequent bonding of edge banding materials (such as PVC, acrylic, etc.), thereby improving the edge banding effect. It aims to improve the edge banding quality and process efficiency, which is one of the core functions of modern edge banding machines. Many automatic edge banding machines are equipped with pre-milling functions, such as Homag, Biesse, SCM, and IMA, which greatly improves the quality and production efficiency of edge banding.

When is pre-milling required?

When the panel (such as MDF, particleboard) has saw marks, broken edges, or uneven edges after being processed by a panel saw or a slitting saw, that is, if the edge of the original panel is uneven, burred, or otherwise rough. At this time, pre-milling must be used for fine processing to ensure that the surface is flat after edge banding and to improve the edge banding quality.

8 Benefits Of Pre-Milling on Edgebander:

1. Remove burrs and unevenness: Premill can remove burrs and unevenness on the edge of the board to ensure a smooth surface after edgebanding

2. Reduce glue line defects: The flat surface after pre-milling can prevent glue overflow or edge banding from lifting, ensuring that the glue line is fine and uniform

3. Enhanced bonding strength: Pre-mill uses a double PCD diamond cutter head to eliminate micro-unevenness of 0.1-0.3mm, remove edge defects and contaminants, and improve the fit of the edge banding by more than 30%.

4. Improve edge banding quality: Pre-milling can make the edge banding material adhere better to the board surface, and improve the adhesion and durability of the edge banding. The first-time qualified rate of the board edge banding after pre-milling is improved, and the rework rate caused by edge defects is reduced.

5. Improve production efficiency: The pre-milling function can process the edges in one go before edge banding, reducing the subsequent trimming process and achieving cost reduction and efficiency improvement in the production process.

6. Save edge banding materials: Premill can ensure smooth edges, reduce waste of edge banding materials, improve the utilization rate of finished products; and control the width of edge banding strips and the amount of glue used to reduce waste.

7. Pre-milling reduces the wear of subsequent edge trimming cutters and reduces maintenance costs

8. Adapt to a variety of materials: Whether it is medium-density fiberboard (MDF), particle board, or plywood, the edge bander pre mill can effectively handle it, ensuring consistent edge quality of different materials

Edgebander Pre-milling tool selection:

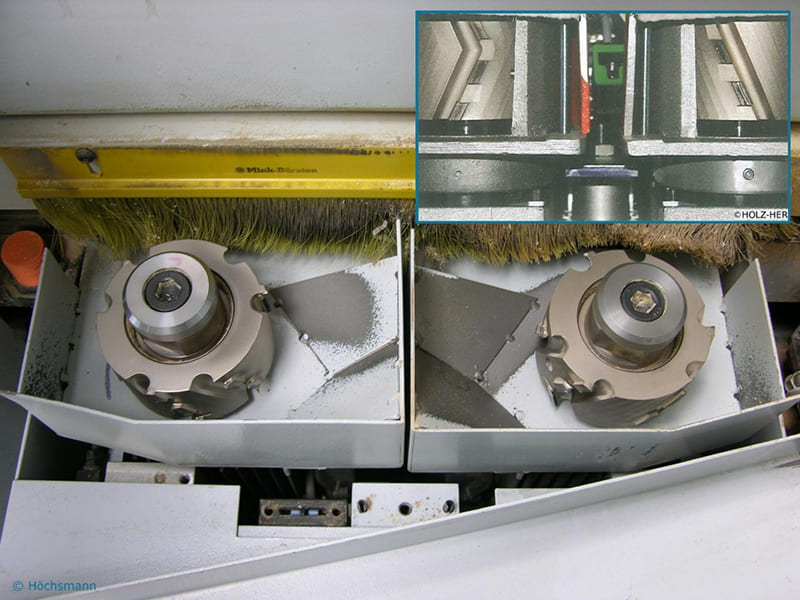

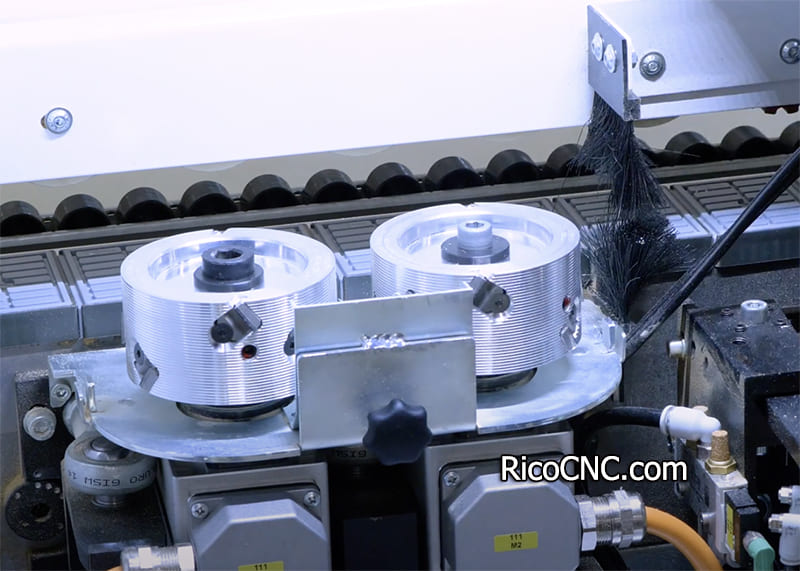

The pre-milling function of an edge bander relies on diamond pre-milling cutters.

Common diamond pre-milling cutters are divided into two types: welded and replaceable.

Welded pre-milling cutters have lower costs, but the blades need to be replaced as a whole after wear;

Although the replaceable premill block has a higher initial cost, it has a lower maintenance cost. It only needs to replace the PCD blade, and has a longer service life and better processing effect.

Pre-milling cutters are divided into left-handed and right-handed directions.

The left-handed direction mills the front end of the panel, and the right-handed cutter head mills the back section of the panel.

The left-handed pre miling cutter is not allowed to mill the back section of the panel, and the right-handed cutter head is not allowed to mill the front section of the panel. The thickness of the panel milled by the premilling tool is adjusted by the tool adjuster, and the PCD cutter head can be adjusted left and right, up and down.

RicoCNC can improve PCD pre-milling cutter heads of different sizes for edgebanders of different brands, such as Homag, Biesse, IMA, OAV, KDT, Bi-Matic, Biesse, OTT, Brandt, Hebrock, Felder, Holzher, Cehisa Laguna, etc.

Pre-milling of edge banding machines plays a vital role. However, pre-milling is not necessary. If you pursue high-quality edge banding and production efficiency, buying an edge banding machine with pre mill units is a very good choice. Premill is worth every penny.

In short, according to specific production needs and processing requirements, choose an edgebander with or without pre-milling station to achieve the best processing effect and production efficiency.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665