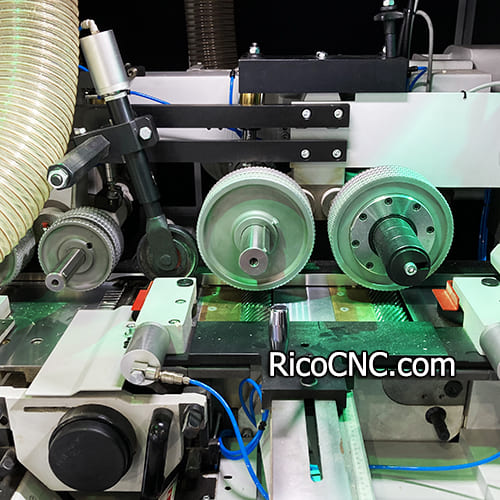

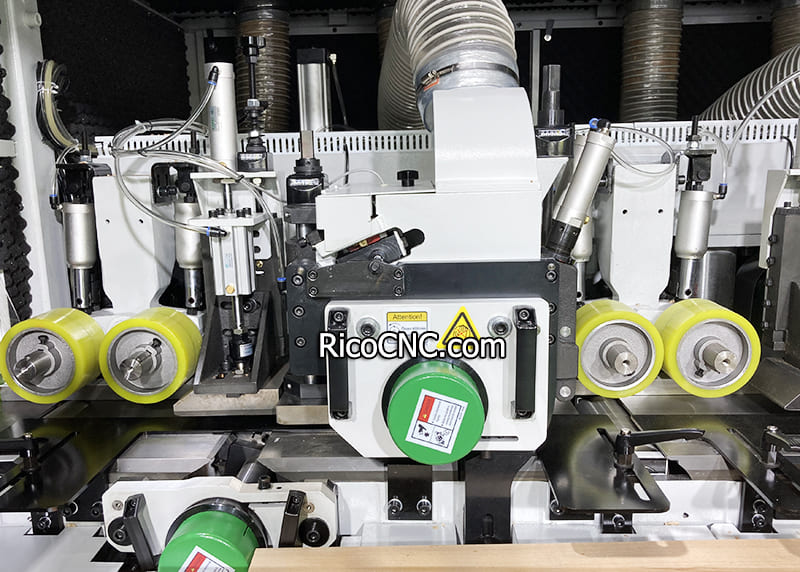

The feed wheel is an important part of the feeding device of the four-sided moulder. It transports the workpiece to the processing area stably and continuously through rotation.

Here are 7 different moulder feed wheel types:

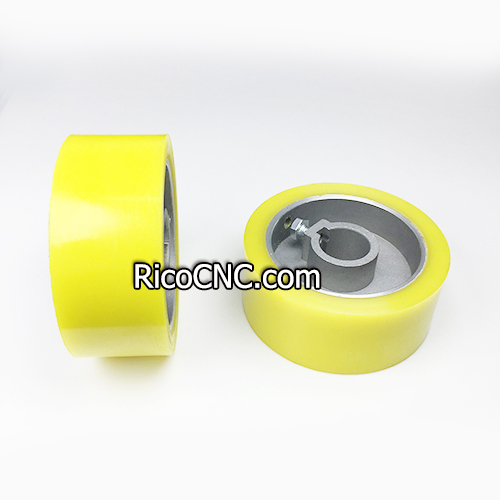

It has good friction and can smoothly transport wood. The rubber feed wheel is suitable for cork and general wood processing. It is specially used for workpieces with high surface requirements or formed surfaces to reduce damage and indentation on the wood surface.

Steel Feed Wheel:

Steel feed wheel is made of high-quality steel with an overall hard chrome plating process, high surface hardness, wear resistance, and strong gripping force, suitable for hardwood or heavy-duty machining. It can withstand large feeding pressure to ensure stable delivery of the workpiece. However, the steel roller may leave indentation marks on the surface of the workpiece, not suitable for high-precision machining.

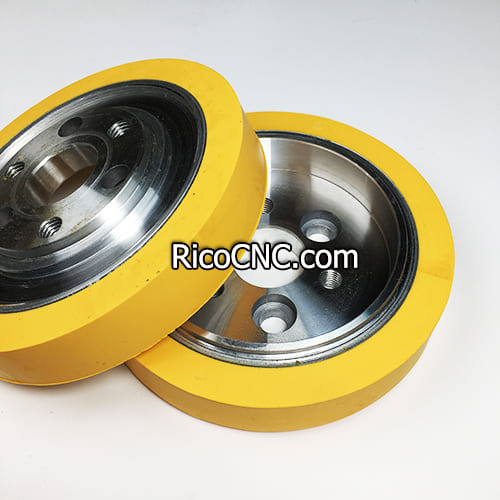

It is harder than a rubber wheel, has both wear resistance and good gripping force, suitable for fine processing. The polyurethane wheel causes less damage to the workpiece surface and is often used in woodworking with higher requirements.

The hub center is equipped with a keyway, which is fixed to the shaft through a key to prevent slipping and ensure stable power transmission. It has high transmission efficiency and is suitable for high-precision processing scenarios.

There are six positioning holes on the wheel surface, which are convenient for installation and adjustment of pressure distribution, good balance, and suitable for synchronous feeding of high-precision wood line machines or four-sided planers.

The surface is smooth, suitable for processing with high requirements on the workpiece surface, and can effectively reduce damage to the workpiece surface.

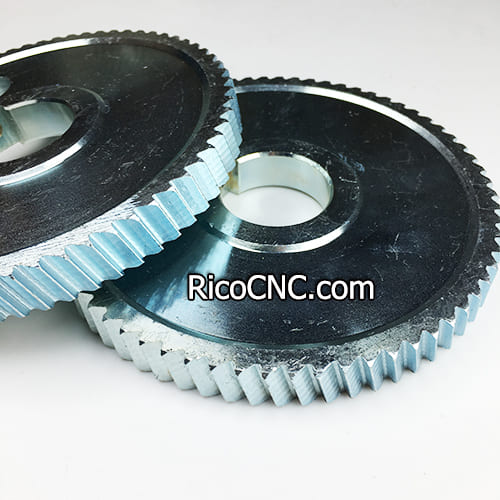

The surface has a toothed or textured design to increase the contact area and friction with the workpiece and has a stronger bite force. The toothed feed wheel is suitable for conveying workpieces with rough surfaces or requiring stronger gripping force, such as rough-processed or barked wood.

There are many different sizes of feed wheels, the most common inner diameters are 30mm and 35mm. And there are different thicknesses, including 20mm, 25mm, 25mm, 30mm, 50mm, etc.

The following are commonly used feed wheel sizes:

Dia=120mm Bore=35mm Wide=60mm

Dia=120mm Bore=30mm Wide=50mm

Dia=120mm Bore=50mm Wide=60mm

Dia=100mm Bore=25mm Wide=60mm

Dia=100mm Bore=30mm Wide=50mm

Dia=140mm Bore=35mm Wide=50mm

Dia=140mm Bore=35mm Wide=25mm

If you need more sizes, don't hesitate to contact us.

RicoCNC can offer a range of replacement planner feed rollers for Weinig planer moulders, four-sided moulders, four-sided planners, SCM moulders, and other woodworking machines.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665