Plywood edgebanding is to wrap or glue the edges of plywood to improve its appearance, enhance edge strength and prevent moisture, dirt, etc. from entering the board, thereby increasing the service life of the plywood. Common edge banding materials include PVC, wood texture, etc. The following is an introduction about best way to edgeband plywood.

1. Choose the right edge banding material

(1) Solid wood strips: Using solid wood strips that match the color and texture of the plywood for edge banding can provide a natural, high-end appearance.

(2) PVC edge banding strips: PVC edge banding is available in a variety of colors and textures, is easy to install, and has a low cost.

(3) Aluminum edge banding tape: Aluminum edge banding has a modern look and is suitable for occasions that require durability and waterproofness.

(4) ABS edge banding tape: ABS edge banding has good wear resistance and impact resistance and is suitable for furniture and interior decoration.

2. Prepare tools and materials

(1) Tools: Electric saw, sandpaper, hot melt glue gun (or special edge banding machine), scraper, scissors, clamps, etc.

(2) Materials: edge banding strip, glue (such as hot melt glue or special edge banding glue), caulking agent, sanding block, etc.

3. Cutting edge banding strip

(1) Measuring size: Accurately measure the length of the edge of the plywood to ensure that the size of the edge banding is appropriate.

(2) Cutting: Use an electric saw or scissors to cut the edge banding to the required length, and make sure the cut is smooth.

4. Gluing edge banding tapes

(1) Hot melt glue method

a. Apply hot melt glue: Use a hot melt glue gun to evenly apply a layer of hot melt glue on the edge of the plywood.

b. Fix the edge banding: Align the edge banding with the edge of the plywood, quickly stick it on and press it with your fingers or a scraper to make it fit tightly.

c. Pressurized fixation: Use a clamp to fix the edge banding to ensure that it is firmly attached. Wait for the hot melt glue to completely cool and solidify.

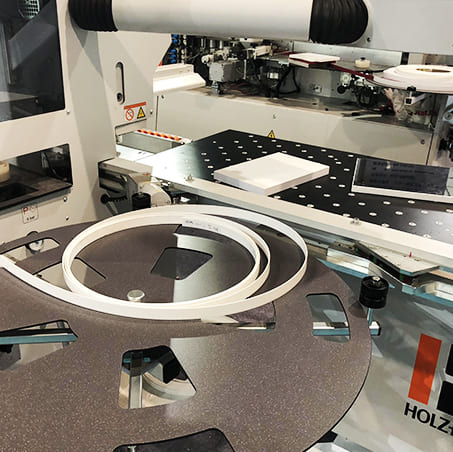

(2) Special edge banding machine method

a. Prepare the edge banding machine: Put the edge banding into the edge banding machine and adjust the temperature and speed.

b. Operate the edge banding machine: Feed the edge of the plywood into the edge banding machine, and the machine will automatically apply glue, adhere and compact the edge banding strips.

c. Trim the excess parts: Use a trimming knife to trim the excess edge banding strips.

5. Handle joints and corners

(1) Joint treatment: If the edge banding strips are spliced in multiple sections, use caulking agent to fill the joints, and then sand them flat after drying.

(2) Corner treatment: For corners, special edge banding corner pieces can be used or they can be processed by manual cutting and splicing.

6. Sanding and trimming

(1) Sanding: Use fine sandpaper to gently sand the surface and edges of the edge banding strips to make them smooth and free of burrs.

(2) Trimming: Check whether the edge banding strips are flat. If there are any uneven areas, continue sanding until you are satisfied.

7. Color matching and polishing

(1) Color matching: If the color of the edge banding strips is slightly different from that of the plywood, you can use a wood repair pen or repair paste to match the color to make them consistent.

(2) Polishing: Use a soft cloth or polishing cloth wheel to polish the edge banding to make it smooth and shiny.

Edgebanding plywood requires comprehensive consideration of material properties, adhesive properties and process adaptability. Mechanical hot melt adhesive edge banding is suitable for efficient production, manual gluing is flexible but relies on operating accuracy, and laser/hot air edge banding meets high-end needs. The key is to ensure that the edge banding is firm and beautiful through precise control of temperature, pressure and glue volume, combined with quality inspection methods such as wood breakage test.

RicoCNC can offer a range of edgebander parts and tools. For more information, welcome to contact us!

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665