The rough and fine trimming of edge banding machines are two key processes in edge banding processing, which have different functions and effects, and directly affect the quality and aesthetics of edge banding. The following are the specific differences and characteristics of the two:

What is rough trimming?

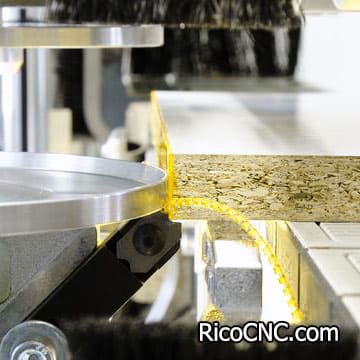

Rough trimming is mainly used to quickly remove most of the excess materials on the upper and lower surfaces of the edge banding strip (such as glue stains or burrs between the edge banding strip and the board), so that the edge banding strip can initially reach a flat state. It is usually completed before fine trimming to provide a basis for subsequent fine trimming.

It is suitable for edge banding of veneer or PVC, acrylic and other edge banding strips with a thickness of more than 1.5mm. If a fine trimming knife is used directly to process thin veneer (such as 0.4mm thick), it may cause breakage.

The rough trimming cutter is a flat knife (straight blade) with no arc, which is suitable for large cutting operations.

The rough trimming knife needs to be wear-resistant and high-strength, and is mostly made of solide carbide to withstand large cutting forces.

What is fine trimming?

Fine trimming is fine processing based on rough trimming. By trimming the edge of the edge banding strip to form an R-shaped arc (or straight edge), the edge banding beauty and precision are improved, and a margin of about 0.05 mm is left for the subsequent scraping process.

Fine trimming is commonly used for PVC and acrylic edge banding strips (0.6-1.5mm thickness) of panel furniture, and it needs to be combined with rough trimming to process thicker edge banding materials.

The fine trimming knife is an R-shaped knife (with arc), which can trim smooth arcs or straight edges to improve the appearance.

The fine trimming cutter requires a sharper blade and often uses high-quality carbide or diamond materials.

Rough trimming is used for preliminary processing, while fine trimming is more delicate, especially when dealing with thicker edge banding strips or veneers.

Rough trimming has a large cutting volume, low precision, and a margin of about 0.5 mm, while fine trimming has a small cutting volume, high precision, and a smaller margin of about 0.05 mm.

Rough trimming and fine trimming are two complementary stages in the edge banding process: rough trimming lays the foundation for fine trimming through efficient material removal, while fine trimming improves the edge banding quality through fine processing. Both are indispensable.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665