In the production of panel furniture, edge banding is the most important and frequently used process, and it is also the process with the most product quality problems. The first and easiest thing to see when judging the quality of a piece of panel furniture is the quality of the edge banding. The following are 5 factors that affect the quality of edge banding.

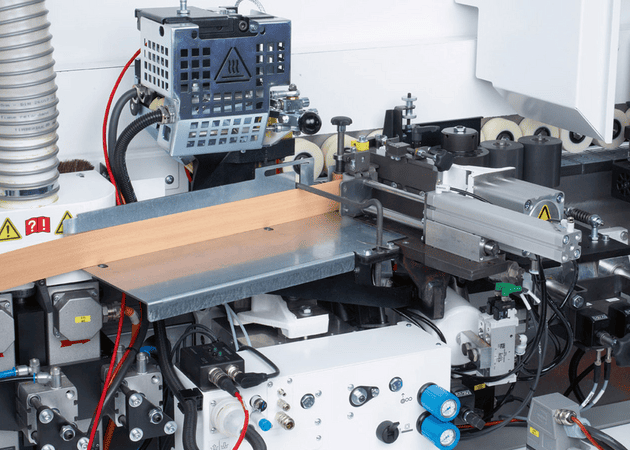

1. Edge Banding Equipment

Because the engine and conveyor belt of the edge banding machine cannot cooperate well, the conveyor belt is not stable during operation and is wavy, causing stress between the edge banding strip and the end face of the board, making the edge of the banding uneven, which is not conducive to the trimming of the equipment (the trimming knife inside the equipment itself); the glue roller and the feed roller do not cooperate well, and the lack of glue or uneven glue coating is very common; the edge trimming cutter and the glue scrapers are often not adjusted well, not only requiring additional trimming by manual labor, but also the trimming quality is difficult to guarantee. In short, the quality problems caused by the poor level of equipment commissioning, repair and maintenance are the most common and the most persistent.

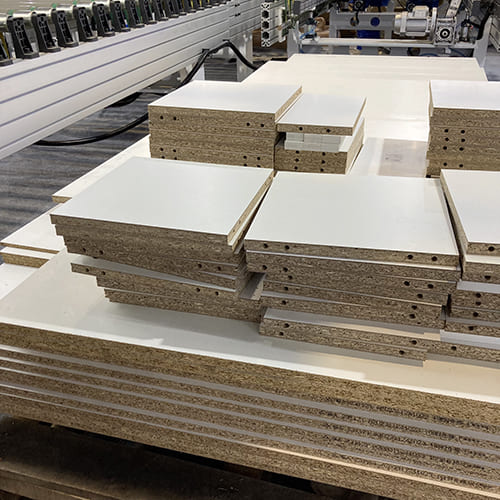

2. Material

As the base material, the thickness deviation of artificial board generally does not meet the standard, mostly showing positive tolerance, and often exceeds the tolerance allowable range (allowable tolerance range 0.1~0.2); the flatness does not meet the standard. This makes it difficult to control the distance from the clamping wheel to the track surface (the thickness of the substrate). If the distance is too small, it is easy to cause over-tightening, increased stress, and debonding; if the distance is too large, the board cannot be pressed tightly, and the edge banding strip cannot ensure a firm bond with the board end.

3. Processing accuracy

During the processing, processing errors mainly come from cutting and fine cutting. Due to the system error of the equipment and the processing error of the workers, the end face of the workpiece cannot reach the level and cannot be kept vertical with the adjacent surface. Therefore, the edge banding strip cannot be fully in contact with the end face of the board during edge sealing. After the edge is sealed, a gap appears or the substrate is exposed, affecting the appearance. What's worse, the substrate collapses during the processing, which is difficult to cover by edge sealing.

4. Edge banding material

Most edge banding materials are PVC, which is greatly affected by the environment. It becomes hard in winter, and its affinity for glue decreases. In addition, the storage time is long and the surface is aged, so the bonding strength to glue is even lower. For paper edge banding with very small thickness, due to its high toughness and small thickness (such as 0.3mm), defects such as uneven edge banding cuts, insufficient bonding strength and poor trimming effect are caused, the rework rate is very high, and the edge banding waste is also very serious.

5. Adhesive

The edge banding uses a special hot-melt adhesive. In winter, due to the low temperature, the temperature of the adhesive should be slightly higher to ensure the bonding strength. If it is too high, exceeding 190℃, the adhesive is too thin, the adhesive layer becomes thinner, and the temperature has dropped when it is applied to the end face of the board. In addition, the edge banding temperature is also low, resulting in a significant decrease in edge banding strength. If the temperature drops to 170℃, the adhesive is a little thicker, but the edge banding temperature is lower, and the adhesive strength is not enough. If the temperature is lower, the adhesive cannot melt well. In production, this contradiction is very prominent and difficult to solve. In addition, the bonding quality of the adhesive itself and the mutual adaptability and affinity between the substrate and the edge banding all affect the edge banding quality.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665