DOOSAN two spindle machining centers are equipped with two spindles, these two main axes greatly improve production efficiency and have options and functions suitable for mass production and automation applications.

Two main axes to improve production efficiency is the optimal solution to optimize initial investment, maintenance costs and time.

Doosan Two-Spindle Machining Centers have two model series: XC 4000-2SP series and VC series. This article will introduce the model features and advantages.

1. XC 4000-2SP series

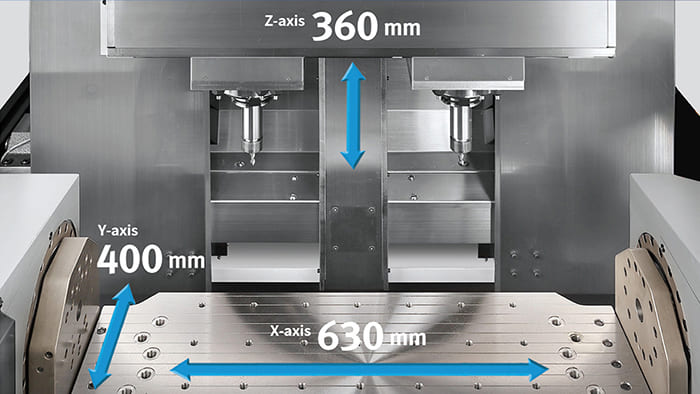

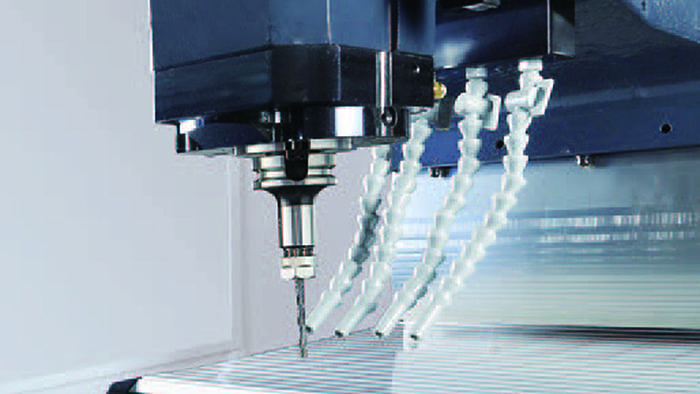

The model number is XC 4000DA-2SP. It is a High productivity double spindle column moving vertical machining center. The XC 4000-2SP dual-spindle vertical machining center is designed to meet the demands of mass production. With two 12000r/min directly-connected spindles, it ensures high-speed machining and boosts productivity. By using a mineral-cast bed, it maintains processing stability and accuracy over long-term production. It is compatible with automated part loading systems, enabling unmanned automation.

XC 4000-2SP series Two-Spindle Machining Center features:

a. Structure optimized for high precision and productivity

The mineral casting bed is used to improve the stability of feed axis during high and low acceleration.

In order to optimize durability and rigidity, a double ball screw structure is adopted.

b. High-rigidity·High-precision

Tool magazines are positioned at the base of the traveling column to ensure high-speed machining performance. (Tool storage capacity: 24*2ea / C-T-C : 3.8 sec)

Automatic door is optimized for high-speed tool change (LM & Pneumatic cylinder driven)

There are many tool magazines accessories for Doosan Machining centers, such as:

Doosan Tool pots/Pocket:

Doosan C37013042B-AY DIN40 Tool pocket MYNX Series DAEWOO Machine

DOOSAN BT50 tool pot for Daewoo Machine Centre

DOOSAN DIN50 tool pot for Doosan HP500 Horizontal Machine Centre

Doosan 101565-00011A DIN40 Tool Pot for DN Machine

C42093782E BT40 Tool Pot for DOOSAN HC500II DAEWOO ADE-HC400

Also Tool holders in many sizes and models supplied here.

c. Meet customers various processing needs

The XC 4000-2SP comes in a variety of dual workbench specifications to meet the needs of different customers and is suitable for automation using robots or trusses.

2. VC series.

The model number is VC 4000D-2SP. It is a Twin-pallet and Twin-spindle VMC for High Production Environments. VC series machining centers have a twin pallet configuration. Their design enables continuous and seamless machining of components - doubling output and significantly increasing productivity.

VC series VC 4000D-2SP Two-Spindle Machining Center features:

a. High rigidity column moving structure

Highly rigid cast structure provides excellent vibration damping and minimizes deformation caused by heavy loads. The column movement design allows for high accuracy even after long periods of operation and minimizes floor space.

b. High productivity by applying the spindle directly (different from the spindle taper)

VC 3600 : ISO #40

VC 3600/30 : ISO #30

c. High-speed automatic pallet changer

Dual tables with standard auto indexing pallets enable table positioning and increase productivity by minimizing standby time.

d. Customization

Customers can choose a variety of types of options according to different processing requirements.

Doosan CNC machine tools can provide customized solutions for different applications and needs. Whether it is metalworking, mold making, aerospace or automotive manufacturing, Doosan CNC machine tools can provide applicable products and technical support. Rico CNC now can supply many Doosan/DN macine tools, not limited to below parts:

Button, Turret Direction ETAPS0149N

Button, Cycle Start ETAPS0116

Button, Rapid F50 ETAPS0135

Cap Knob Turret Move 110910-00840

Wiper Z-Axis (L) L31602142A

Doosan PUMA 2100SY # ML0360-000064

130510-00268 BALL SCREW;X1-AXIS 110912-00041A R32-8K6-FSC-505-787-0.005

130510-00269 BALL SCREW;Y-AXIS 300418-00313 R32-10K5-FSC-400-750-0.005

130510-00270 BALL SCREW;Z1/B-AXIS 300418-00275A R40-10K4-FSCC-1020-1365-0.008

130510-00697 BALL SCREW;X2 1 10912-00044B R-32-10K3-FSC-330-590-0.005

130510-00271 BALL SCREW;Z2-AXIS 300418-00276A R40-10K4-FSCC-1110-1455-0.008

L62422016A X-AXIS BALL SCREW 1R32-10T4-1FSDA-425-753-0.008 for PUMA 2100MS

DOOSAN 301308-00287 marposs Touch Probe for Tool Setting Q4124013000 sensor /Q4124015000 replaced

DOOSAN SERVO MOTOR VISION DS-RH20TC-10O 300508-00146A

RAA-001207-2102 model is for 12 staton tool

RAA-000807-2102 model is for 8 staton tool For doosan puma240

Doosan Bed Cover, Factory PN# 110508-41141.

Doosan DNM 4000 VC: MV0117-000166 100702-01140B-01

Doosan DVF 5000 MV0111 000880 130510017770B

11092400727A

Puma 600XL ML0163000036 22021000105

Puma4100XLB ML0282000025 22021000951A

Puma 400XLMB ML0142000172 L33412123A

Bearings NTN 64 5S- LA-HSE014 DBCS11-IP4 (Ceramic)

Bearing NTN 112 N1011HSR CONAUP-5

110958-04697A

110958-04700

400302-00037A

P8000550

R55454

R55283

R10101

P80300018

110446-00115

110446-00174

110408-00329A

L62570157

850418-00276

850418-00713A

...

More parts please contact us freely!

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665