The horizontal machining centers from Doosan/DN Machine Tools feature a high-speed, high-precision feed system and a fast, compact Footprint that allows for efficient use of space.

This article will introduce the model series of DOOSAN Horizontal Machining Centers and their main necessary accessories.

DOOSAN Horizontal Machining Centers have below series:

HC ll series: HC 400 II, HC 500 II

HM Series(China): HM 635 II, HM 805 II

HM series: HM 1000, HM 1250, HM 1250W

NHM series: NHM 5000, NHM 6300, NHM 8000

NHM series(China): NHM 6305, NHM 8005

NHP Series(China): NHP 5005, NHP 5550, NHP 6350, NHP 8005, NHP 8005S

NHP series: NHP 4000, NHP 5000, NHP 5000S, NHP 5500 2nd Generation, NHP 6300, NHP 8000

NHC series: NHC 4000, NHC 5000

HC ll series: HC 400 II, HC 500 II

The HCII series is the perfect economical horizontal machining center for a wide range of machining requirements with an expandable tool changer and pallet magazine.

HC ll series horizontal machining centers features:

a. Optimized design

A new, aesthetically pleasing and simplified design that greatly simplifies machine operation.

b. Increased productivity

The new spindle speeds of up to 12,000 rpm and the wider range of tool magazine and automation options dramatically increase versatility and productivity.

c. Improved ergonomics

The new design of the operator panel and built-in pallet-mounted switches improves the ergonomics of the machine.

HM Series(China): HM 635Ⅱ, HM 805Ⅱ

The HM Series(China) is fully Rigid Guideway High Rigidity Heavy Cutting Horizontal Machining Center.

HM Series(China) horizontal machining centers features:

a. High rigidity box-type guideway enables high torque and improves the overall heavy cutting capability of the machine.

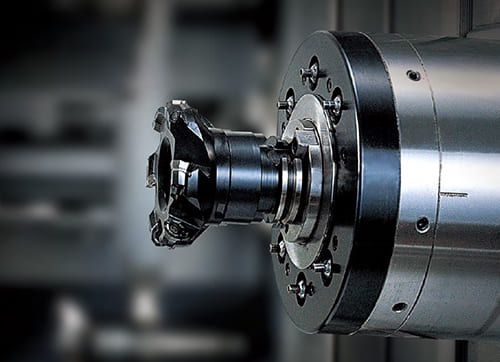

b. Optimized ATC structure reduces vibration and prevents tools from falling off more effectively when exchanging tools.

c. APC structure with additional bearing between table center axis and piston improves durability during exchange.

DOOSAN control panel and MPG supplied here:

HC115 Electronic Handwheel for Doosan

HC121AB Mitsubishi Handwheel for Doosan

HM series: HM 1000, HM 1250, HM 1250W

Equipped with high torque and an automatic pallet changer, the HM series from DN Machine Tools is the optimal choice for customers who require high efficiency, hard-tracked horizontal machining centres for large parts.

HM series horizontal machining centers features:

a. Increased productivity and improved performance specifications

High-torque gearbox spindles, hard rails, and high-rigidity cast structures all contribute to high productivity.

b. General machining to W-axis machining possible

Selection of pallet sizes from 1000/1250 models and optional boring and milling W-axis.

c. Automatic pallet changing system as standard

In-line pallet changer for long-term operation and automation.

NHM series: NHM 5000, NHM 6300, NHM 8000

The NHM horizontal machining centers deliver the power, performance and reliability component manufacturers need for the heavy-duty machining of tough and difficult materials.

NHM series horizontal machining centers features:

a. Highly rigid one-piece bed

This highly rigid one-piece bed has been analysed using the Finite Element Method (FEM), allowing for highly rigid heavy-duty machining.

b. High reliability and productivity

Servo-driven automatic tool changer (ATC) and automatic pallet changer improve component durability for easy maintenance. Compatibility with pallet extension systems and minimisation of downtime increases productivity.

c. Ease of Use

Ease of use is dramatically improved with a wide range of easy-to-operate functions as standard equipment.

NHM series(China): NHM 6305, NHM 8005

NHM series(China) is a #50 Horizontal Machining Centres for Hard Gauge Heavy Duty Machining

The NHM series(China) offers high rigidity, heavy-duty machining capabilities to meet a wide range of customer needs for heavy-duty machining. The fully hardened, one-piece bed provides highly stable, powerful machining of parts. Servo tool changer and table changer dramatically reduce non-cutting time for high productivity.

NHM series(China) horizontal machining centers features:

a. One-piece bed structure and high rigidity wide hard rail achieve stability during heavy cutting and ensure high accuracy during machining. b. Servo-driven ATC and automatic pallet changer reduce non-cutting time and greatly increase productivity. c. The machine is designed to be used in a variety of applications.

b. Servo-driven ATC and automatic pallet changer reduces non-cutting time and improves productivity.

c. Standard FANUC system for efficient automated production line customers to provide a convenient, but also according to the production requirements and plant structure can be equipped with multi-pallet system and linear pallet system, to achieve intelligent production needs.

NHP Series(China): NHP 5005, NHP 5550, NHP 6350, NHP 8005, NHP 8005S

The NHP series has high productivity and a wide range of products to meet the diversified needs of customers. The NHP series has high speed and powerful cutting ability, good machining performance and production capacity.

NHP Series(China) horizontal machining centers features:

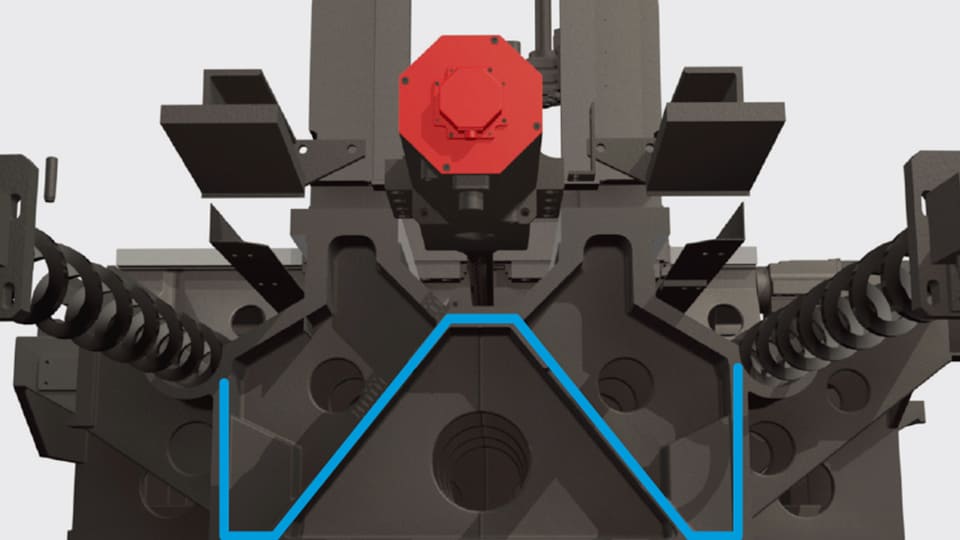

a. High rigidity bed structure

The stepped guideway bed structure supports the column stably and achieves high rigidity.

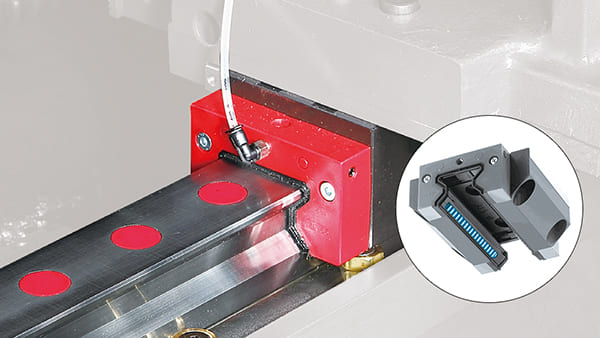

Highly rigid, high-precision roller type linear guideway.

There are many Roller Type Linear Guideway and ball type linear guide guideway accessories supplied here.

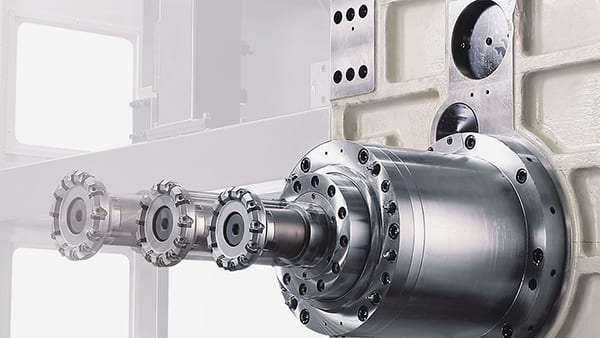

b. High-speed, high-performance spindle

Reduced vibration and thermal error during high-speed machining, good acceleration and deceleration performance.

High-torque built-in electric spindle

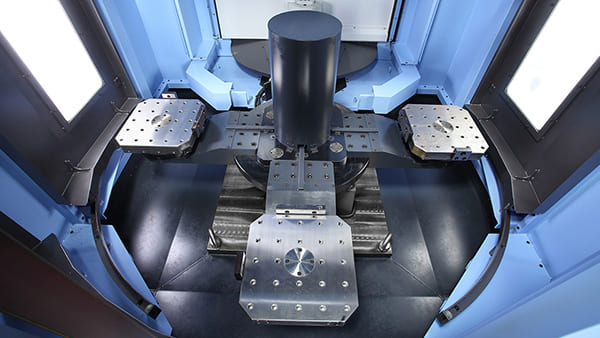

c. Automation solutions

Space-saving optimised design for automated production lines

Linear pallet systems (LPS), round pallet systems (RPS) and single pallet systems

NHP series: NHP 4000, NHP 5000, NHP 5000S, NHP 5500 2nd Generation, NHP 6300, NHP 8000

NHP series machines are productive, efficient and cost-effective. With their compact size and featuring high performance linear guideways and powerful spindles NHP machines deliver high material removal rates - day in …day out.

NHP series horizontal machining centers features:

a. Highly rigid stepped guide rails

The body is designed with a double-wall structure that prevents coolant leakage and achieves excellent maintainability.

The stepped guideway bed structure stably supports the column and achieves high rigidity.

b. High productivity and reliability

All axes are equipped with roller-type linear guides, and the servo-driven automatic tool changer (ATC) and automatic pallet changer increase component durability and maintainability for improved product quality. Compatibility with pallet extension systems and minimised downtime increases productivity.

c. Pallet Automation Systems

Doosan Machine Tools' Linear Pallet System (LPS) and Multi-Pallet System (MPS) provide users with the highest levels of productivity, quick setup and commissioning, and easy maintenance.

NHC series: NHC 4000, NHC 5000

The NHC Series, offering compact horizontal machining, is designed to provide maximum productivity and accuracy, with a number of convenient features. The compact design efficiently utilizes limited factory space.

NHC series horizontal machining centers features:

a. Enhanced Design

Improved Appearance and Functional Design:

A new design was applied considering user convenience, and usability was increased with a touch screen and a wide screen.

b. Increased Productivity

The 15000r/min direct spindle option was added to expand customer choice and productivity was maximized by increasing rapid traverse.

c. Increased User Convenience

Newly designed operation panel and built-in pallet setup switch further improves ergonomics of the machine.

Doosan CNC machine tools can provide customized solutions for different applications and needs. Whether it is metalworking, mold making, aerospace or automotive manufacturing, Doosan CNC machine tools can provide applicable products and technical support. Rico CNC now can supply many Doosan/DN macine tools, not limited to below parts:

850412-00052 DIN40 CAT40 Gripper Tool Claw Collet Assy for Doosan Daewoo DNM DMC FFGDMC Machine

Doosan Collet DIN50 850412-01228 R76628A for Doosan Daewoo DNM DMC FFGDMC Machine

Doosan Daewoo Machine Tool Claw BT40 850412-00678A for CMV MYNX NM Series

Doosan BT50 850412-00963A R76629 CNC Gripper

Kwangwoo Manual Encoder Wheel RIM-80-0100-BVA for DOOSAN Machines

Doosan 301411-00100B DN Sensor Touch for DN Machine

301417-00031 Safety Door Switch Doosan Machine Tool STP3A-537A024MC2363

GSBF02R12-502-MC1806 EUCHNER 094147 Limit Switch Position Switch Doosan ESWLM0059B

DOOSAN Servo Drive DVSC-TM-28C 300419-00036B Servo Drive

DOOSAN 300632-00183 Manual Pulse Generator RE46A1CD5

Doosan 300692-00126 MPG Manual Pulse Generator Hand Wheel

DOOSAN R30765A Parker D1VW001CNJWL Hydraulic Directional Solenoid Valve 24VDC

Button, Turret Direction ETAPS0149N

Button, Cycle Start ETAPS0116

Button, Rapid F50 ETAPS0135

Cap Knob Turret Move 110910-00840

Wiper Z-Axis (L) L31602142A

Doosan PUMA 2100SY # ML0360-000064

130510-00268 BALL SCREW;X1-AXIS 110912-00041A R32-8K6-FSC-505-787-0.005

130510-00269 BALL SCREW;Y-AXIS 300418-00313 R32-10K5-FSC-400-750-0.005

130510-00270 BALL SCREW;Z1/B-AXIS 300418-00275A R40-10K4-FSCC-1020-1365-0.008

130510-00697 BALL SCREW;X2 1 10912-00044B R-32-10K3-FSC-330-590-0.005

130510-00271 BALL SCREW;Z2-AXIS 300418-00276A R40-10K4-FSCC-1110-1455-0.008

L62422016A X-AXIS BALL SCREW 1R32-10T4-1FSDA-425-753-0.008 for PUMA 2100MS

DOOSAN 301308-00287 marposs Touch Probe for Tool Setting Q4124013000 sensor /Q4124015000 replaced

DOOSAN SERVO MOTOR VISION DS-RH20TC-10O 300508-00146A

RAA-001207-2102 model is for 12 staton tool

RAA-000807-2102 model is for 8 staton tool For doosan puma240

Doosan Bed Cover, Factory PN# 110508-41141.

110958-04697A

110958-04700

400302-00037A

P8000550

R55454

R55283

R10101

P80300018

110446-00115

110446-00174

110408-00329A

L62570157

850418-00276

850418-00713A

More parts please contact us freely!

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665