Vacuum pump carbon vanes, also known as graphite vanes, are precision components manufactured from carbon-graphite materials. These vanes are widely used in rotary vane vacuum pumps, where they are installed in the rotor slots and sealed inside the pump housing. When lubricated with vacuum pump oil, increasing the contact area between the vacuum pump carbon vanes and the housing wall enhances the pump’s ability to achieve optimal vacuum levels. However, if the vacuum pump carbon vanes are too short or thin, insufficient vacuum or even severe pump failure may occur.

Wear judgment criteria of Vacuum pump carbon vanes

1. The surface cracks of the carbon sheet are more than 3mm, or the cracks extend to the edge of the carbon sheet, it must be replaced.

2. The thickness of single carbon vane is worn more than 1/3 of the original thickness (the original thickness is usually 5-8mm, please refer to the instruction manual of the equipment).

3. The contact surface between the carbon plate and the pump chamber has obvious grooves, and the depth of the grooves is more than 0.5mm.

4. The difference in the degree of wear of several carbon chips is too large (such as the difference in the thickness of neighboring carbon chips is more than 1 mm), and the whole set needs to be replaced.

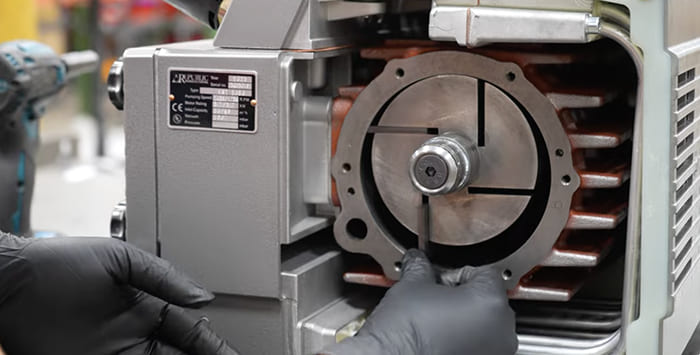

Replacement operation points for Vacuum pump carbon vanes

1. Before disassembling the pump, turn off the power and rotate the pressure relief valve to the pressure relief position to prevent parts from being ejected due to residual vacuum. Record the installation order when removing the old carbon disk, and install the new carbon disk in the original order.

2. Clean the pump chamber and rotary vane groove with anhydrous ethanol before assembly, and prohibit the use of fabric containing fibers for wiping. Rotate the pump shaft manually to test whether it is stuck or not, if there is resistance, you need to readjust the position of the carbon disk.

3. Clean the cylinder wall of the air pump before installing and replacing the carbon veneer, without any residue;

4. Check whether the cylinder wall is worn out (Note: If you come across a bad carbon disk, the hardness is too high and it will easily wear out the cylinder wall);

5. When installing the carbon vane, pay attention to the direction of the chamfering must not be installed in the opposite direction, that will soon break the carbon vane;

6. Regularly maintain the bearings of the air pump and add high-temperature lubricant, such as bearing damage will lead to unexpected failures, with serious consequences;

7. air inlet filter element to maintain good working performance, regular replacement, maintenance.

8. Wear goggles when operating to prevent splashing of broken carbon chips. It is forbidden to touch the metal parts inside the pump chamber with bare hands, the residual oil may cause skin allergy.

9. Hand over the discarded carbon chips to the professional organization according to the standard of industrial solid waste disposal, and do not discard them at will.

Special Situations happened for Vacuum pump carbon vanes

Difficulty in starting the unit after a short period of inactivity may be due to moisture expansion of the carbon vanes, disassemble and place in an oven at 80°C for 2 hours to dry, if it still cannot be reset then replace. If the pumping rate is not restored after replacing the carbon vanes, check whether the spring has failed or whether there are scratches in the pump chamber. If metal rubbing sound occurs during the operation of the equipment, stop the machine immediately, it may be due to the broken carbon vanes causing direct contact with metal parts.

Spare carbon vanes Storage Requirements

Store unused carbon vanes in a dry, light-proof environment with a relative humidity of less than 60%. After the whole package of carbon vanes is opened, if it is not used up within half a year, it should be resealed by vacuum bag. Mixing different brands of carbon vanes may lead to air leakage, and it is recommended to use original spare parts when replacing them.

Advantages of High-Quality Vacuum Pump Carbon Vanes

1. self-lubricating carbon vanes, with strong wear resistance; can withstand high temperature, no need to use vacuum pump oil and water as a medium, more energy-saving;

2. more environmentally friendly, no pollution, because self-lubricating carbon vane has light carbon particles will be discharged from the exhaust port. More efficient, more suitable for high-speed dynamic rotation of the vacuum pump.

3. It has high elastic limit, excellent fatigue resistance and can adapt to high intensity pump operation.

4. The carbon element in the material is mainly in the form of carbon monomers, i.e. free graphite, the port is dark gray, resulting in higher hardness of the vacuum pump carbon vane fine piece, and better wear resistance.

5. The product shape design is reasonable, the surface roughness is reduced, and the surface strengthening treatment is adopted to provide the anti-fatigue performance of the vacuum pump carbon vanes, and the vacuum pump carbon vanes can be self-lubricating and adapt to the long time and high temperature operation.

Selecting premium vacuum pump carbon vanes extends service life, lowers maintenance costs, and ensures operational stability. Proper handling, storage, and adherence to wear criteria are vital for peak performance. By prioritizing quality and routine care, users can maximize efficiency and reliability in vacuum pump systems.

Becker vacuum pump vanes are the best quality vanes in the market, Rico can supply all models of Becker vanes, please check our website-https://vacuumpumppart.com/, there are many brands carbon vanes: BECKER, BUSCH, ELMO RIETSCHLE, ORION. Contact us for details!

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665