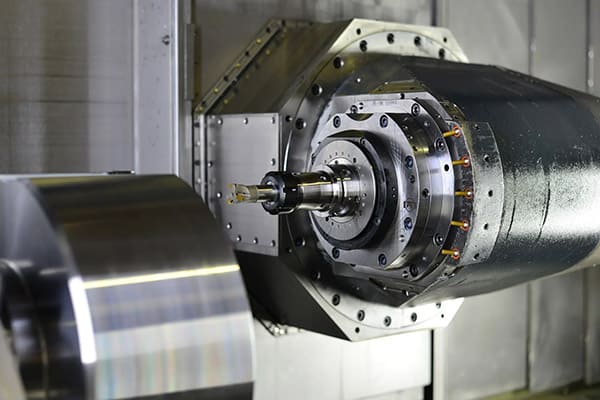

The CNC spindle is the core component of precision engraving machines, directly impacting processing accuracy and equipment lifespan. However, spindle damage is common in daily use, primarily due to improper operation, cooling system failure, environmental factors, or spindle quality issues. Below, we analyze these common causes of spindle failure and provide solutions to extend spindle lifespan.

1. Improper operation leads to spindle damage

The spindle of the precision engraving machine needs to maintain the appropriate speed during processing, otherwise it is easy to cause bearing wear or even damage. Common problems include:

The spindle starts machining without reaching the set speed. When the spindle is running at a low speed, the bearing lubrication is not sufficient, if the cutting load is applied at this time, it will lead to excessive friction on the bearings and accelerate wear.

Failure to adjust the speed according to the material. Different materials have different cutting resistance, such as metal, acrylic, wood, etc. The required speed varies greatly. If the speed is too high when machining hard materials or too low when machining soft materials, it will increase the load on the spindle and shorten bearing life in the long run.

Rico recommends that you wait until the spindle reaches the set speed before starting cutting. Choose the right speed according to the material characteristics and avoid overloading the spindle for long periods of time.

2. Cooling system failure leads to spindle overheating

The spindle of the precision engraving machine will generate a lot of heat when running at high speed, if the cooling system is not able to dissipate the heat effectively, it will lead to damage to the bearings due to high temperature expansion. Common cooling problems include:

Poor water circulation. Clogged cooling water pipes (e.g., internal rust, scale buildup, or external water pipe bends) will result in insufficient coolant flow and the spindle will not be able to dissipate heat adequately.

Forgetting to turn on the cooling system. Some operators may be negligent and fail to activate the water or oil cooling system during machining, resulting in a rapid rise in spindle temperature over a short period of time and seized or worn out bearings due to thermal expansion and contraction.

Rico recommends that the cooling system be checked regularly to ensure that the water lines are clear and to avoid the buildup of impurities. Make sure the cooling system is turned on before machining and observe if the water flow is normal. Use purified water or specialized coolant to reduce scale formation.

3. Freezing of spindles due to low temperatures (water-cooled spindles)

In cold regions, water-cooled spindles can be damaged by freezing of the coolant. The water expands as it freezes and can cause:

Cooling pipes to rupture. Rupture of cooling pipes. The expansion force of the ice can crack internal waterways or external water pipes of the spindle.

Deformation of the internal structure of the spindle. If the waterway is deformed due to freezing, the accuracy of the spindle may be compromised, even leading to seized bearings.

Rico recommends using antifreeze coolant or switching to an oil cooling system at low temperatures. Thoroughly empty the cooling water after stopping the machine to prevent residual water from freezing. Keep the workshop temperature above 5°C to avoid spindle frostbite.

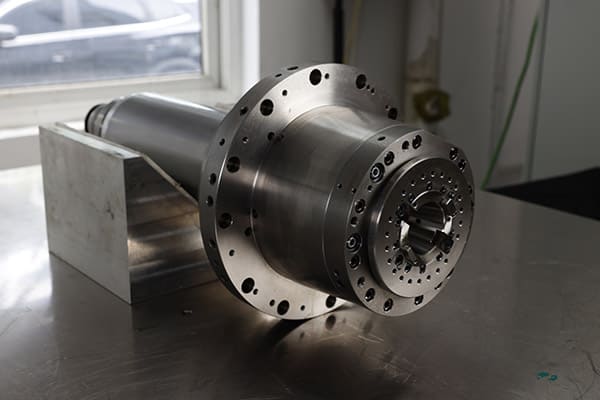

4. Spindle itself quality problems

Part of the spindle damage is caused by manufacturing process or material problems, common situations include:

Poor quality bearings. Poor quality bearings are prone to wear, heat and even shatter at high speeds.

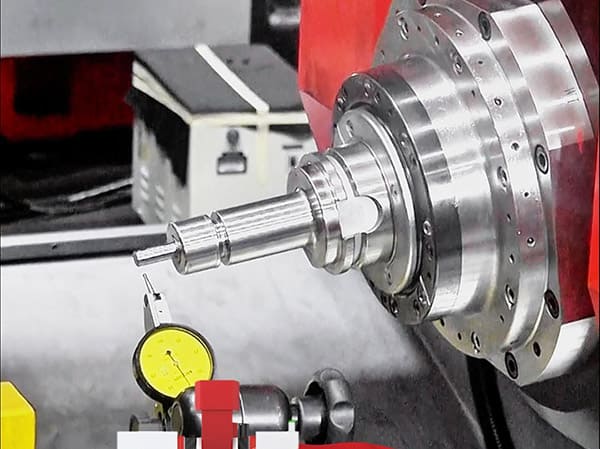

Substandard dynamic balancing. A spindle that is poorly balanced at high rotational speeds will vibrate violently and accelerate bearing wear.

Insufficient assembly precision. If the internal parts of the spindle clearance is too large or too small, it will affect the stability of operation.

Rico suggests choosing spindles of well-known brands to ensure the quality of bearings and assembly. New spindles should be dynamically balanced after installation to ensure smooth operation. Regularly check the spindle vibration, find abnormalities and timely troubleshooting.

Damage to the spindle of the precision engraving machine is often caused by operation, maintenance or environmental factors, rather than a sudden occurrence. Through standardized operation, regular maintenance of the cooling system, pay attention to the ambient temperature and choose high-quality spindles, you can significantly reduce the failure rate and extend the service life of the equipment. In daily use, it is recommended to establish spindle maintenance records, timely detection and resolution of problems to ensure processing efficiency and equipment stability.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665