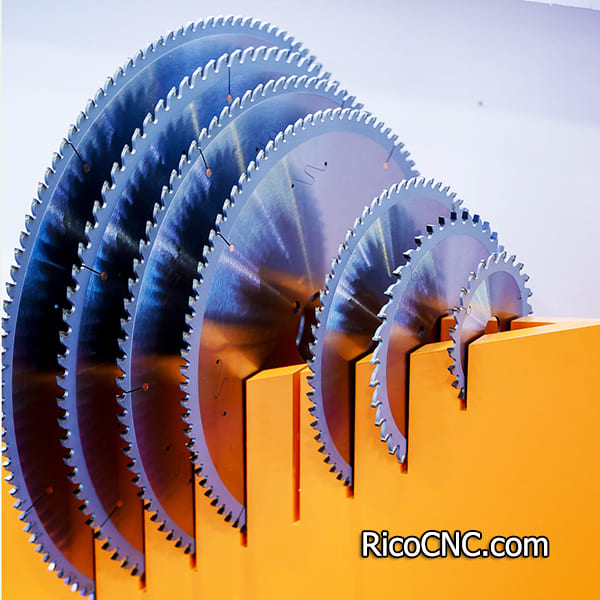

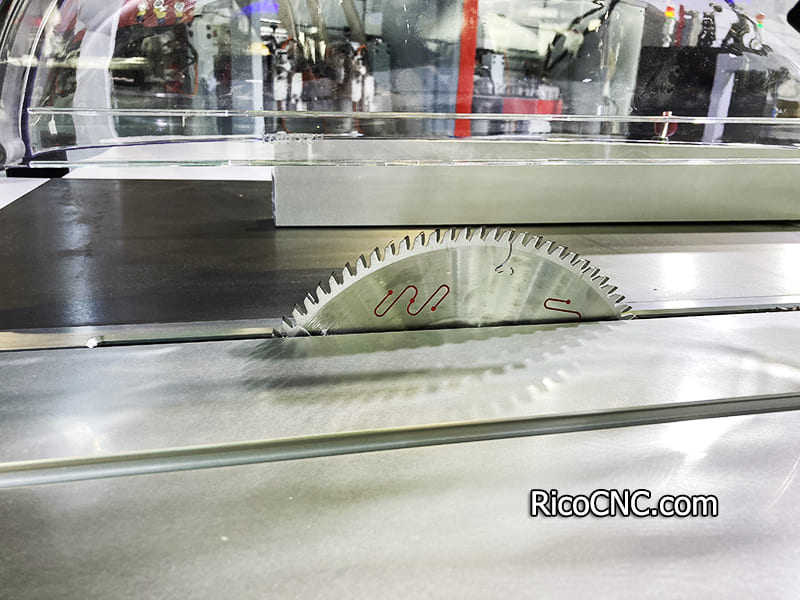

Carbide saw blades are widely used in woodworking due to their high hardness, strong wear resistance, and sharp cutting. However, as the use time increases, the cutting performance of the saw blade will gradually decrease, affecting the processing efficiency and product quality. In order to extend the service life of the carbide saw blade and ensure the cutting effect, it is particularly important to regularly sharpen and maintain the saw blade.

So, what details should be paid special attention to during the actual grinding process? The following are 12 key precautions when sharpening carbide saw blades for your reference.

1. The quality of coolant teeth sharpening depends on the grinding fluid. A large amount of tungsten and diamond wheel powder is generated during grinding. If the tool surface is not rinsed and the grinding wheel pores are not cleaned in time, the surface grinding tool cannot be ground to a smooth finish, and insufficient cooling will also burn the alloy.

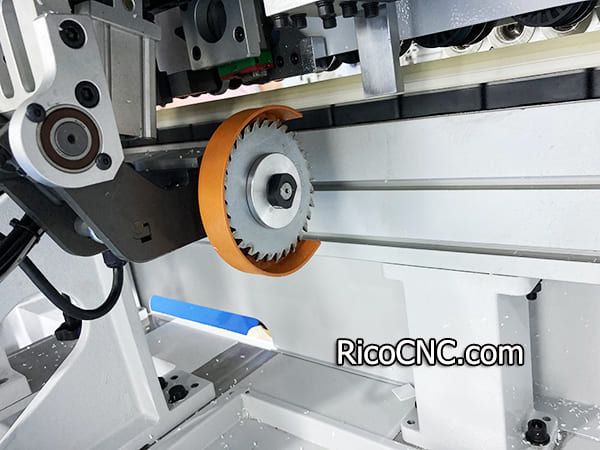

2. The influence of the teeth grinding mechanism on teeth grinding. The quality of carbide saw blade teeth sharpening depends on the machine structure and assembly. There are about two types of models on the market: one is the German Fulmer type. This type adopts vertical grinding, which has the advantages of all using hydraulic stepless motion, all feeding systems using V-shaped guide rails and ball screws, the grinding head or arm uses slow advance and fast retraction, the clamping cylinder adjusts the center, the support is flexible and reliable, the tooth extraction is accurately positioned, the carbide circular saw blade positioning center is firm and automatically centered, any angle adjustment, reasonable cooling and flushing, human-machine interface, high grinding precision, and reasonable design of pure grinders; the second type is the current horizontal type, such as Taiwan and Japanese models, the mechanical transmission has gears and mechanical clearances, the dovetail sliding precision is poor, the clamping performance is low, the support center is difficult to adjust, the tooth extraction mechanism or reliability is poor, the two sides of the plane and the left and right back angles are not ground at the same center, resulting in large deviations, difficult angle control, and large mechanical wear, making it difficult to ensure accuracy.

3. Welding factors. The large deviation of alloy degree during welding affects the grinding accuracy, causing one side of the grinding head to be under greater pressure and the other side to be under less pressure. The back angle also produces the above factors, the welding angle difference, and the unavoidable human factors all have an unavoidable impact on the grinding wheel and other factors during grinding.

4. Influence of grinding wheel quality and grain width. It will

directly affect the effect of carbide saw blade sharpening tools. So

When choosing a diamond grinding wheel to sharpen carbide saw

blades, pay attention to the grinding wheel grain size. Grinding with

too coarse grain will produce grinding wheel marks. Grinding wheels with

fine grains are prone to clogging, small grinding volume, and easy to

burn the knife. The diameter and width and thickness of the grinding

wheel are determined according to the length, width, narrowness,

different tooth shapes, and various surfaces of the alloy. It is not

possible to grind different tooth shapes at will with the same back

angle or front angle grinding wheel specifications. You must choose a

grinding wheel with appropriate specifications in a targeted manner.

5.Grinding head feed speed. The quality of carbide saw blade sharpening is completely determined by the grinding head feed speed. Generally, the feeding speed of carbide circular saw blades should not exceed 0.5 to 6 mm/s. That is, it should be within 20 teeth per minute. If the feeding speed exceeds 20 teeth per minute, it will cause serious blade tumors or burnt alloy, and the grinding wheel will have convex and concave surfaces, which will affect the grinding accuracy and waste the grinding wheel.

6. The grinding head feed rate and the grinding wheel size are extremely important to the feed rate. Generally, it is recommended to use 180# to 240# grinding wheels, and 240# to 280# is recommended. 280# to 320# is not recommended. Otherwise, the feed speed needs to be adjusted.

7.Grinding center. All carbide tip saw blades should be ground with the base as the center, not with the blade edge. The surface grinding center cannot be taken out, and the back angle and front angle processing center cannot grind a saw blade well. The saw blade center of the three processes cannot be ignored. When grinding the side angle, the alloy thickness should still be carefully observed. The grinding center will change with different thicknesses. Regardless of the alloy thickness, the grinding wheel center line should be kept in a straight line with the welding position when grinding the surface, otherwise the angle difference will affect the cutting.

8.The gear extraction mechanism cannot be ignored. Regardless of the structure of any gear grinding machine, the accuracy of the gear extraction coordinate design is related to the quality of the grinding knife. When adjusting the machine, the gear extraction needle is pressed at a reasonable position on the tooth surface, and it is also extremely important not to move. When withdrawing the teeth, the gear extraction claws should be flexible and reliable.

9.Clip mechanism: The clip mechanism is firm, stable and reliable, and is the main part of the knife sharpening quality. The clip mechanism must not be loose at all during any knife sharpening, otherwise the grinding deviation will be seriously out of control.

10.Grinding stroke. Regardless of which part of carbide circular saw blade is being ground, the grinding stroke of the grinding head is very important. Generally, the grinding wheel is required to extend 1 mm beyond the workpiece or to be withdrawn 1 mm, otherwise two-sided cutting edges will be produced on the tooth surface.

11.Program selection: There are generally three different program options for carbide saw blade sharpening: coarse, fine, and grinding. The selection depends on the requirements for the product. It is recommended to use the fine grinding program when grinding the front angle.

12.The matrix is deformed, the thickness is inconsistent, and the inner hole tolerance is large. When the above-mentioned congenital defects of the matrix exist, there will be grinding errors regardless of the type of equipment used. The large deformation of the matrix will cause deviations in the two side angles; the inconsistent thickness of the matrix will cause deviations in the back angle and the front angle of the blade. If the cumulative tolerance is too large, the quality and accuracy of carbide circular saw blade will be seriously affected.

RicoCNC can provide different sizes of carbide saw blade and diamond saw blade of different sizes, and can provide customized services.

For more information, please contact us!

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665