DMG MORI is a global leader in advanced CNC machine tools, formed through the merger of Germany’s DMG and Japan’s MORI SEIKI, combining German precision engineering with Japanese manufacturing excellence. The company specializes in turning, milling, additive manufacturing, and automation solutions, offering high-end products such as 5-axis machining centers, turn-mill centers, and laser processing machines, all integrated with its innovative CELOS digital platform for Industry 4.0 smart manufacturing. Renowned for precision, dynamic performance, and reliability, DMG MORI serves demanding industries like aerospace, automotive, and medical technology, with operations in over 30 countries. Through continuous R&D and sustainable manufacturing technologies, the company remains at the forefront of metalworking innovation.

What are the commonly used accessories for DMG MORI machining centers and turning-milling composite machines? Let's take a look:

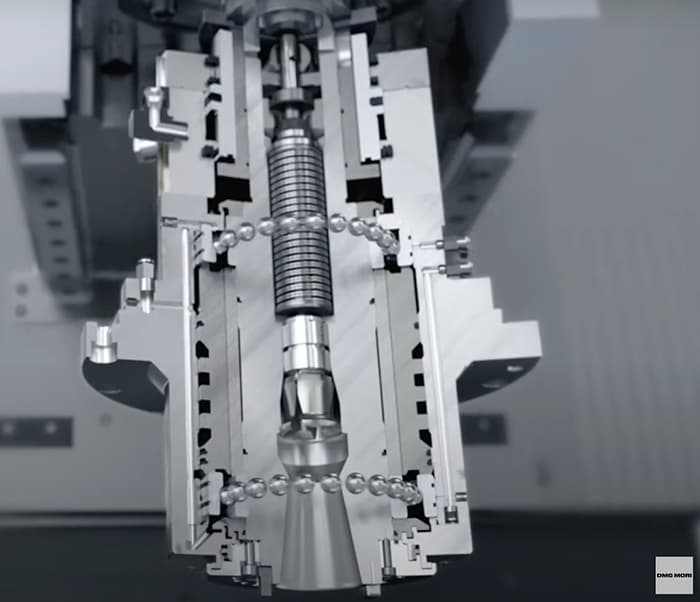

1. Spindle system

DMG MORI mostly uses its own spindle brand: MORI SEIKI Spindles Traditional high-rigidity spindles for turning centers and heavy-duty machine tools The spindle provides power and precision → The Tool Clamping System ensures tool stability → The rotary joint provides cooling/lubrication

There are many kinds of tool clamping grippers for DMG MORI spindle:

BT.CAT-40 401033 K60195A; 401011 K60127A;

BT.CAT-40 406048 K60088A01 HV4000;

DIN-40 407032 K60090A01 NH8000 DCG;407037 K60089A;

BT-40 MAS-1 407038 K60091A;410016 K60128A;

BT-40 MAS-2 410017 K60129A;407039 K60092A;410011 K60125A NHX4000;411001 K60132A NHC6300st ;

JIS.DIN-40 414004 K60141A;JIS.DIN-40 490029 K60041A;

BT.CAT-50 403017 K60207A NH8000DCG;

BT.CAT-50 407043 K60094A01 NH8000DCG;

BT.CAT-50 407051 K60102A01 NH5000DCG;

BT.CAT-50 406049 K60093A01;

DIN-50 407046 K60100A01 NH8000DCG; 407042 K60097A;

BT.CAT-50 407047 K60101A01;

480008 K60000 MV55;

BT-50 MAS-1 407040 K60095A

BT-50 MAS-2 402012 K60204A;407041 K60099A;

MH-50 488058 K60036

JIS-DIN-40 490029 K60041

1037451 for DMG HSK Taper

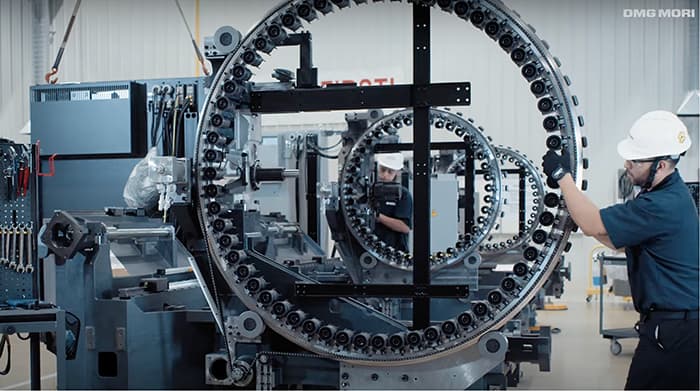

2. Tool Magazine

DMG MORI's tool magazine system achieves efficient and reliable automatic tool changing through the coordinated operation of its components. The system features a chain or disc structure equipped with tool holders and protective covers to effectively prevent processing debris from entering. The drive unit consists of a high-performance servo motor combined with a precision reducer, which ensures smooth operation through synchronous belts or gear drives.

Tool changing is performed by an ATC robotic arm, which works in conjunction with pneumatic clamping devices to ensure precise and reliable tool exchange. The system integrates RFID identification and proximity sensing technology, with optional barcode scanning functionality, enabling intelligent tool management.

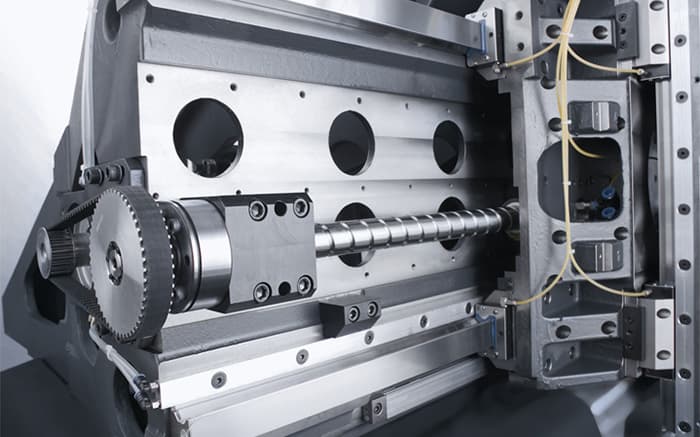

3. Linear Guide Systems

DMG MORI machine tools use high-precision linear guides and ball screw technology in their motion systems to ensure outstanding dynamic performance and positioning accuracy. DMG MORI linear guide system brands are THK, Rexroth, INA and IKO.

As machines are used, most DMG MORI machine parts need to be replaced and maintained. As users of second-hand DMG machine tools, most people choose third-party parts suppliers because they have a higher level of service awareness and offer highly cost-effective parts options. Rico CNC, as a one-stop supplier of CNC machine tool parts, can provide more parts replacement solutions for DMG MORI machine tools.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665