BT50 vs DIN50 CNC Gripper

Most customers often need to identify the model of their gripper when making a selection. Therefore, we will analyse real-life cases to illustrate how to distinguish between different gripper models when choosing.

When the customer asked for a quote, he provided us with the model number of the puller that he found on the internet to fit his machine: Doosan R76628A. We confirmed that it was the Doosan 850412-01228 DIN50 puller according to the model number he gave us and sent him a quote, and the customer was very happy to buy this puller.

However, when he replaced the original puller, he found that the puller could not hold the previous shank.

In fact, what he actually should have purchased was R76629 Doosan BT50 CNC gripper!

How can we distinguish between BT50 and DIN50 puller grips? How do we choose the right puller?

1.The first step was to confirm the brand of the CNC gripper, and the customer was correct in his judgment that Doosan pull-grips are used on Doosan machines.

2.Confirming the models of Pull studs: BT50 vs DIN50 pull studs

Pull studs (also called retention knobs) are the link between the CNC gripper and the tool holder. BT50 and DIN50 pull studs (retention knobs) are used in machining centers to secure the tool holder in the spindle. Despite their similar purpose, they have distinct differences based on their standards and specifications.

BT50: This is based on the Japanese standard (JIS B 6339). BT pull studs are typically used with BT tool holders, which are symmetric around the spindle axis and provide high rigidity and balance.

DIN50: This is based on the German standard (DIN 69872). DIN pull studs are used with DIN tool holders and are designed according to European standards.

We can identify the model of a pull stud by examining the shape of its top.

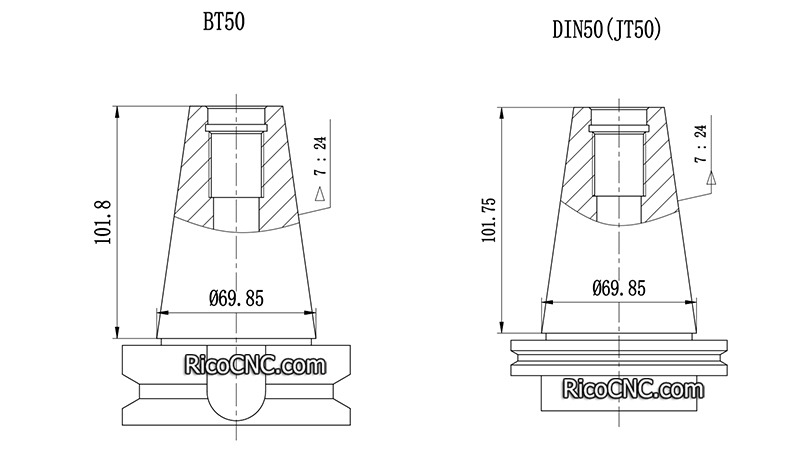

From the images, we can see that the BT50 pull stud has a larger curvature at the top, whereas the DIN50 pull stud has a smaller incline, almost flat.

The top of the pull stud is the area that comes into direct contact with the gripper, so the design of the gripper jaws is determined based on the contact surface with the pull stud. As seen in the images, the gripper jaws for the DIN50 have a very small curvature, while those for the BT50 have a larger curvature, appearing more uneven.

From the middle of the pull stud, the middle length of the BT50 pull stud will be larger than the DIN50 pull stud.

3.Confirmation of tool holder type, BT50 vs DIN50 tool holders

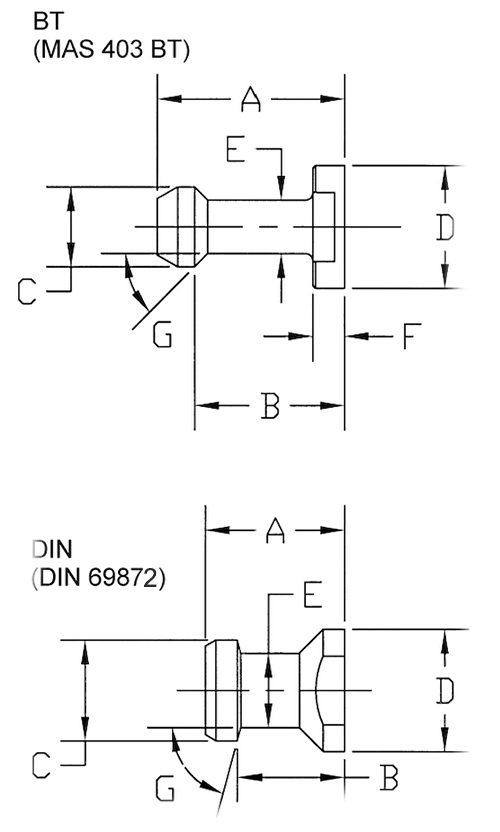

BT50 shank and DIN50 / JT50 shank taper are the same, are taper 7:24. But the two shanks of the manufacturing standard are not the same, BT50 collet chuck shank is the Japanese standard MAS-403, DIN50 tool holder shank is the German standard DIN 69871.

The difference between the BT50 collet chuck shank and the DIN50 collet chuck shank is that the manipulator clamping part is different from the pull stud, the BT50 tool chuck shank flange is thicker, the manipulator clamping groove is close to the side of the tool, the depth of the two end keyways are the same and are not milled through; the DIN50 tool chuck shank flange thickness is smaller, there is a notch to locate the tool with the loaded tool, and the depth of the two end keyways are different and are milled through.

To summarize how to choose a pull grip

To ensure we provide you with the correct pull stud, please provide as much of the following information as possible:

1.Machine Brand and Model

Specify the brand and exact model of your machine. This helps us understand the specifications and compatibility requirements.

2.Clear Pictures of the Pull Stud

Provide clear images of the pull stud, including detailed photos of the pull stud piece. If the pull stud has any model numbers or codes, make sure these are clearly visible in the photos.

3.Clear Pictures of the Tool Holder

Provide clear images of the tool holder. If there are any model numbers on the tool holder, please capture them clearly in the photos.

4.Clear Pictures of the Retention Knob

Provide clear images of the retention knob. This helps us identify the type and specifications of the retention knob.

5.Spindle Model and Pictures

Provide the model of the spindle where the pull stud is used, along with clear images. This helps us ensure compatibility between the spindle and the pull stud.

The more detailed the information you provide, the more accurately and quickly we can help you find the correct pull stud. This will allow you to solve machine issues promptly, resume operations faster, and reduce downtime and associated costs.

Choose Rico, Machine Troubleshooting, Create and Deliver Value

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665