As a Wooden Furniture Manufacturer, Plenty of furniture-making machines are needed according to the specific task and the scale of production. Such as router machines, beam saws, edge banding machines, etc. Today, we’ll talk about a common wooden furniture machine and its spare parts and wearing parts.

In a furniture factory, you should have the following machine to produce furniture at least.

Beam saw machine: Beam saw is mainly used for cutting large wood and boards, it has a large blade used to cut different-sized logs into beams. Such as making furniture, doors windows, etc. Beam saws are the most effective method of precise panel cutting with modern software.

Beam saws wearing parts: Air Flotation Spring Ball Valve, Pressure Bar Strip, Curtain guard, PCD Diamond Tipped Circular Saw Blades.

CNC router machine: it is used for various materials. Like wood, plywood, MDF, and plastic, CNC router machines have changed the woodworking industry. These machines can automatically cut, and carve different shapes with high precision, no matter whether small businesses or large-scale manufacturers alike, they should have CNC router machines.

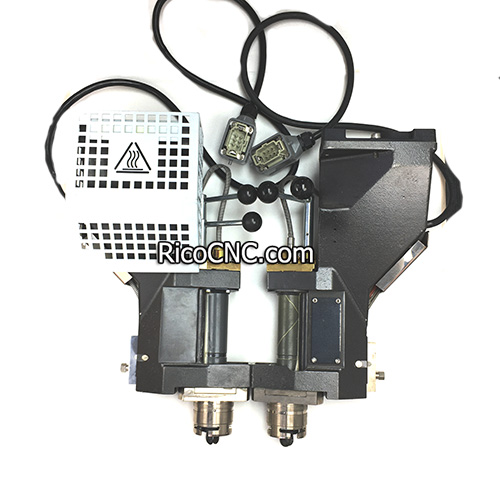

CNC router machine wearing parts: router bits, CNC foam mill cutter, tool holder, tool fork, collect, spindle, gripper, vacuum pod, rubber gasket, handwheel, spindle runout test bar, Becker vane, etc.

CNC Drilling Machine: it can finish grooving and milling at one time. Easy to operate, flexible to use, free from manual intervention.

Apply to cabinets, wardrobes, office furniture, custom furniture, computer desks, panel furniture, wood speakers, wooden kitchenware,e and other panel furniture plane cutting, milling, chamfering, punching, engraving, and other auxiliary processing.

Edge banding machine: This machine is used to apply a strip of material to the exposed edges of panel products like plywood or particle board.

Ender banding machine wearing parts: feed roller, trackpads, glue pot, etc.

CNC automatic lathe machine: It is used for creating symmetrical objects around an axis of rotation, such as table legs or other round elements of furniture.

Lathe machine wearing parts: CNC RC-V, RC-X wood lathe tools, 2in1 wood lathe tools, 3in1 wood lathe tools.

Sander: A sander is used for smoothing the wood’s surface. You will find belt sanders, orbital sanders, and disc sanders.

Sure, you have a lot of optional machines for your special needs: table saw, nesting CNC machine, cutting machine, vacuum press machine, polishing machine, drill press, door lock hole machine, etc.

As a one-stop CNC spare parts shop, RicoCNC is glad to try our best to help you solve machine troubleshooting. We supply above wearing parts but are not limited to other spare parts, like cylinders, linear bearing blocks, blet, limit switches, sensors, solenoid valves, servo motors, servo drives, etc.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665