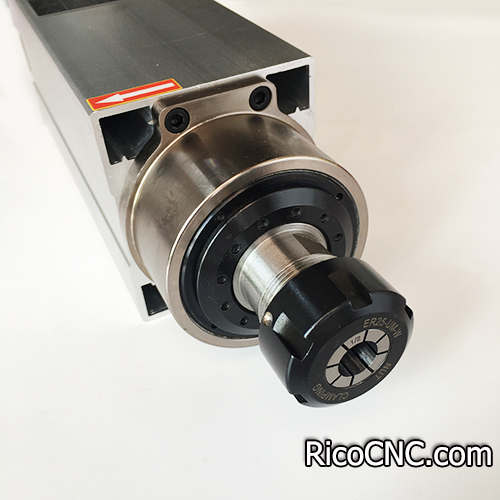

Air Cooled Spindle (air cooling spindle) and Water Cooled Spindle (water-cooling spindle) can be used in the CNC woodworking industry. they are belongs to common CNC spindle (CNC spindle motor). You can find the spindle often be found in lathes, CNC routers, and other CNC machines.

The spindle's main function is as follows:

Rotate: The spindle rotates at high speeds, also the speed can be changed based on the technical requirements.

Hold the tool holder: Spindles have a tool holder or a collet to make that cutting tool can be held in a steady status. There is no doubt that it can ensure stability and precision during the machining process.

Power Transmission: Spindles transmit power from the machine’s motor to the cutting tool.

After knowing the importance of the air-cooled spindly and water cooler spindle, worker maintenance realized getting more and more important, we’ll aim to the air-cooled spindly and water cooler spindle, share with you some tips and teach you how to maintenance.

Air Cooled Spindle and Water Cooled Spindle Maintenance:

1. Please frequently clean the water outlet and inlet with hooks, to prevent rubbish from clogging the water hose.

2. When disassembling the spindle is removed from the CNC router machine, please use an air gun to blow off the fluid in the cooling chamber of the electric spindle.

3. Please use oil-sealed if it is a long time of no use;

4. When restart, do not remove the rust on the surface with gasoline, also:

1) Grease the mist for 3-5 minutes, twist the shaft by hand

2) A megohmmeter should be more than 10 megohms.

3) speed can be increased gradually, like within the first hour, the spindle runs at 1/3 rated RPM, if everything is ok, increase speed up 1/2 rated RPM for the next one hour, if ok, and then run 1 hour at the full speed.

5. During the using the spindle, increase rpm gradually per 10 minutes, until up to 6000RPM.

Also, we need to notice that. Do not let the spindly cut the woodworkpiece until runs at full speed, because this improper operation can damage the spindle's life.

6. A rear-mounted coaxial fan cools the air-cooled CNC spindle. The rooted speed cannot be lower than 7000RPM.

7. Please set the appropriate feeding speed, Improper feed rates can negatively impact spindle life.

8. The electro-spindle cannot have a collision with any other objects, including the tool change process.

9. Do not let the top of the air-cooled spindle enter into the dust from the fan.

By carefully reading these tips, you can use your water-cooled or air-cooled spindle well. Sure, if you are in the purchasing the CNC spindle stage, you can RicoCNC, we can offer you a series of CNC spare tools for woodworking tools, like spindle, CNC grippers, servo motors, servo drives, and sensor... We can offer you a full professional solution.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665