HSK63A and HSK63F are two common CNC tool holders in the industry. They both follow the standard of the HSK tool holder system, which is the German standard DIN69873. Their flange diameters are both 63mm, and they are both commonly used in CNC machining centers with automatic tool changers.

So, what are the main differences between HSK63A and HSK63F tool holder? Here are 5 important differences we summarize for your reference.

1. Different Taper Dimension

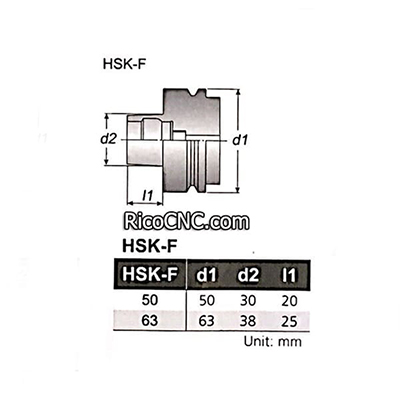

As shown in the dimension drawing of HSK63A and HSK63F tool holder, d2 and l1 are different, which naturally leads to different tapers.

d2 refers to the cone diameter, HSK63A tool holder is 48mm, HSK63F is 38mm;

l1 is the shank holder length, HSK63A toolholder is 32mm, HSK63F is 25mm.

So, the taper dimension of HSK63F tool holder is smaller. That is to say, HSK63F dimension and HSK63A dimension are different.

It should be noted that the taper size of the HSK63F tool holder is the same as that of the HSK50A tool holder. Therefore, they can use the same model and size of HSK63F spindle gripper. Pay attention to this when purchasing a spindle pull gripper for your CNC machines.

2. Different Appearance

HSK63A tool holder has the drive slot, manual fixing hole, and direction slot, while HSK63F holder does not have.

3. Different Rotation Speeds

HSK63F tool holder has a smaller taper, so HSK63F’s rotation speed is higher. Generally,up to 24000RPM;

HSK63A tool holder’s speed is lower, generally medium speed, 15000 to 20000RPM.

4. Different Torque

HSK63A has the drive slot, while HSK63F does not. Therefore, the torque of the HSK63A toolholder is relatively large, and it is more suitable for heavy cutting. While, the torque of HSK63F toolholder is relatively small, and it is suitable for light cutting.

5. Different Application

HSK63F tool holders are suitable for CNC woodworking machines for wood processing

HSK63A tool holders are suitable for CNC metalworking machines for metal processing.

Due to different application areas, the plastic tool holder forks used are different in appearance. As shown in the pictures below, HSK63F tool holders mostly use this white HSK63F tool holder fork, while HSK63A uses this black HSK63A tool holder fork. But in fact, although plastic tool holders look different, the dimensions of the tool holder jaws are usually the same, which means that in some cases, they can be used interchangeably.

RFQ:

1. Are HSK63A and HSK63F tool holder dimension the same?

HSK63A and HSK63F dimension are not the same. They have the same flange diameter of 63mm, but they are different.

2. Will HSK63A toolholder fit in an HSK63F spindle?

HSK63A tool holders are not compatible with HSK63F spindles. Because their tapers are different, the CNC spindles and spindle gripper used are also different. HSK63F tool holders fit HSK63F spindle grippers; HSK63A tool holders fits HSK63A spindle gripper.

3. What type of collets do HSK63F holders use?

HSK63F holders usually use ER collet and OZ collet (also known as RDO/SYOZ/EOC collet). When purchasing a CNC collet, you can check the model number on the tool holder, which is usually marked, such as HSK63F-ER32, which means an ER32 collet is required.

4. Can HSK63A and HSK63F tool holder use the same tool holder tightening fixture?

Yes, they can use the same tool holder tightening fixture HSK63. As their flange diameters are the same.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665