Edge banding machines are a very important tools for any wood manufacturer. Regular maintenance is crucial for keeping your edge bander productive. If you have a Homag edgebander in your workshop, below are some essential maintenance tips for Homag edge bander you should know.

Clean your Homag edgebanding machine:

1. Clean the edgebander every week, it is recommended to use dry compressed air and a dry cloth to clean the machine.

2. Lubricate the upper pressure device and height adjustment rail every month (run twice in the height direction)

3. Check the conveyor belt drive gearbox motor for overheating, abnormal noise, and other faults every three months. The oil in the gearbox should be replaced with new oil every three years.

4. Replace the damaged conveyor chain pads. Note: When replacing a new conveyor track pad, soak the new conveyor block in hot water at about 60°C before pressing it onto the conveyor chain!

5. Check and adjust the tension of the conveyor chain every six months to prevent the trackpad from buckling.

6. Lubricate the conveyor track pads and chain with oil every week.

7. Clean the compressed air filter element every quarter. The oil and water that are normally filtered out are automatically drained.

8. Check the functioning of the inflatable spring support bar and protection switch on the edge banding machine guard flap every six months,

9. Computer check

Remove the filter screen and clean it every 2 weeks to ensure normal heat dissipation and ventilation. Clean the computer control cabinet with a hoover every 6 months.

Caution:

- Do not switch on the control power supply while the computer is starting up!

- It is forbidden to switch off the power supply suddenly while the computer is performing the uploading and downloading of parameters!

- The computer must be shut down according to normal procedures!

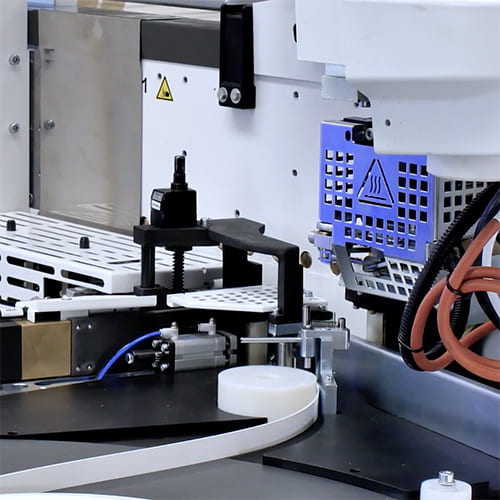

Check the glue application system:

1. Lubricate the glue roller bearings with high temperature oil every two days.

2. Clean the gluing unit every month (do not use sharp-edged tools for cleaning).

3. Clean the drive universal joint shaft every 6 weeks.

Check the feeding system:

Clean and lubricate the conveyor chain and the feed roller from the lubrication nozzles every month.

Check the rubber pressure wheel area:

Weekly lubricate of the drive bearings of the large pressure roller.

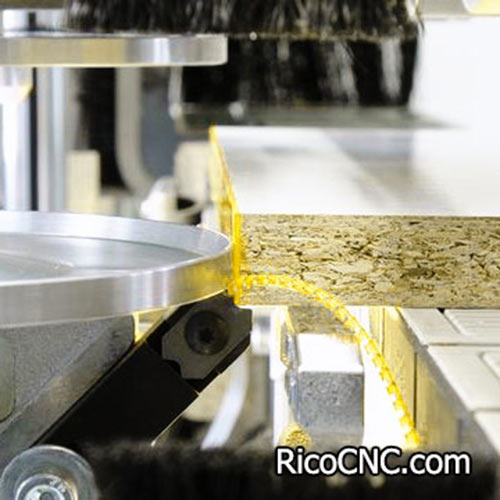

Check of front and rear trimming areas:

1. Check the linear guide on the groove every season and move it back and forth to check the wear.

2. Manually check the down buffer of the front trimming and the up buffer of the front and rear trimming every month

3. Lubricate the guide slider with grease every 2 weeks and visually check whether all guide rails are automatically lubricated.

4. Weekly inspect and adjust the oil-air lubrication unit of the guideway sliders, refill, and adjustment of the atomized oil volume

Rough/fine trimming up and down:

Clean and lubricate floating guide rods and other moving parts monthly. Keep moving parts in good elastic condition.

Edgebander tools:

1. Weekly inspection of the suction hood.

2. Weekly clean suction hood.

3. Every six months check the cutter for damage and the digital gauge for accuracy.

Rounded corner tracking trimming:

1. Check the basic air pressure setting of the pneumatic unit weekly.

2. Check and adjust the automatic oil mist lubrication system weekly. Add oil and adjust the amount of atomized oil.

Scraper trimming:

1. Maintain the chip breaker quarterly. Use a thin steel sheet to break the scraped strips.

2. Clean and lubricate the floating guide rod and other moving parts every week to ensure that the horizontal and vertical wheels are always close to the workpiece; avoid the scraped strips getting stuck between the wheels and the workpiece and affecting the edge sealing effect (mainly the dust suction wind force and the presence or absence of adjust the blowing angle).

Glue scraping device:

1. Check the tool for wear or damage every quarter.

2. Clean the edge bander spindle and moving parts and apply lubricating oil every month.

Polishing device:

Clean and adjust the spindle every quarter, and adjust or replace the worn polishing cloth wheel.

Keep some basic spare parts for your HOMAG edgebanding machine on hand.

To reduce the downtime of your edgebanding machine, it is advisable to keep a stock of commonly used Homag spare parts, such as rubber pressure wheels, chain track pads, diamond pre-milling cutters, scrapers, gas shock absorbers, etc.

Regular maintenance of edge banding machines is very important. It can not only greatly extend the service life of the machine, but also keep the edge banding machine in the best working condition. It can reduce downtime caused by parts damage. The maintenance of edge banding machines is actually a small investment to obtain greater benefits. Take action now!

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665