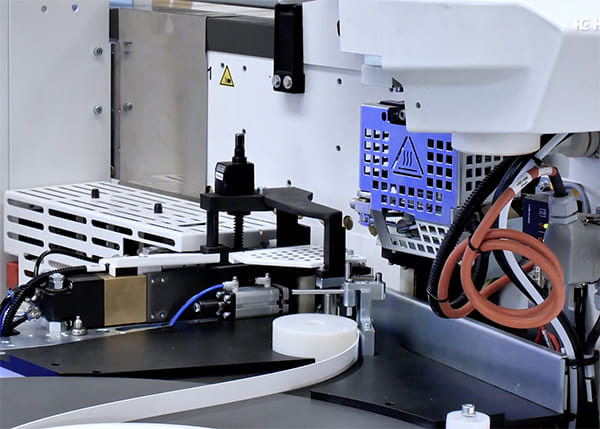

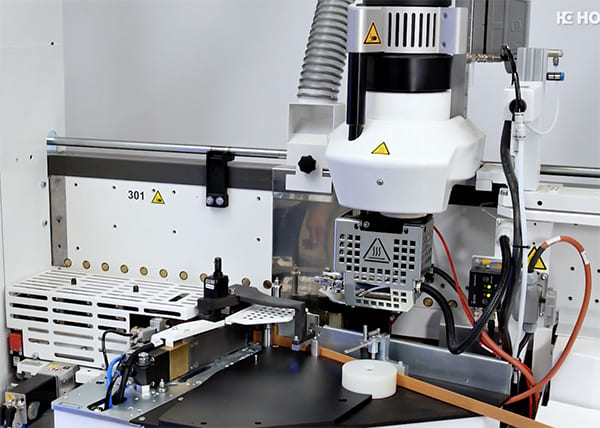

The glue pot is a vital part of the edge banding machine. It is called the heart of the edge banding machine. The glue pot is used to melt the sol particles into liquid glue by heating, and then send the glue liquid to the gluing roller through the conveying device. The glue roller applies the adhesive to the board's edge and the edge banding strip respectively to perform edge banding. Therefore, it is essential to regularly inspect and maintain the glue pot. Otherwise, it will affect the edge banding effect and the quality of the workpiece.

Homag is a leading brand of woodworking machinery, and its edge banding machines have a huge market share. In order to ensure the efficient operation and extended service life of Homag edge banding machines, regular maintenance of the glue pot is essential. The following is a detailed maintenance guide for the glue pot of Homag edge banders.

Remove the glue pot:

1. When the temperature of the glue pot is heated to about 180°C, point the heating icon on the computer to 0 and stop heating.

2. Turn off the start switch of the glue roller

3. Remove the glue level sensor above the glue pot while it is still hot. (Note that the glue level sensor inside is wrapped by residual glue, and forcibly removing it will damage the glue sensor)

4. Loosen the handle screw and remove the top glue tank.

5. Clean the residual glue in the hexagonal screw hole that fixes the glue tank

6. Use a 6mm long hexagonal wrench to remove the fixing screw.

7. Remove the glue pot protective cover, unplug the power plug, and remove the power cord.

8. Use the U-shaped handle to lift the glue pot and take it out.

Remove the glue roller:

The glue roller is the core component of the edge bander glue pot. It rotates rapidly at high temperatures for a long time, which can easily cause the parts on the glue shaft to age and wear easily.

How to remove the glue roller:

1. The temperature of the glue pot should be kept above 160°C.

2. Remove the 4 M6*30 hexagon socket screws on the base of the glue roller.

3. Open the two glue gates.

4. Pull out the glue roller from the bottom.

5. Remove the central heating tube. Do not spray WD-40 on high-temperature parts

6. Remove the four M6 screws that fix the copper component and remove the copper component. 4008400057 Paper pad: 4012010589

7. When the glue roller cools to room temperature, take it out with the copper component and soak it in glue remover.

8. After about a week, when the residual glue on the shaft becomes soft and easy to remove, take it out and clean it.

9. Remove the locking nut at the lower end of the glue roller and take out the stop washer, retaining ring, iron oil seal, etc.

10. Use a wooden board to support the glue roller fixing seat and press it out.

11. Take out the two bearings and the shaft sleeve.

12. Clean the disassembled parts.

Disassembly of glue roller components:

1. Remove the slotted nut at the shaft end

2. Take out the three washers and pay attention to the order of the washers

4. Replace the seal when worn; replace the bearing when worn

5. Please check the lower base of the glue roller to see if the high-temperature oil filling hole is open.

Copper component part:

1. Be careful not to damage the seal ring when installing it, and the metal circlip mouth should face outward. Part number: 4012010608

2. The metal ring mouth should face the shaft downward. Seal ring 4012010408

Install the glue roller:

1. Check whether the glue spindle is damaged.

2. Check whether the inside of the spindle is clean and check the internal copper sleeve.

3. Replace the O-ring on the spindle.

4. Install the square sleeve by hand.

5. Install two 6005 bearings (pry off the iron seal on the opposite side of the bearing)

6. Install the bearings and wash off the lubricating oil inside.

7. Tighten the slotted nut, and then turn the glue shaft to be able to turn easily. If not, check whether the nut is locked too tight and reassemble it.

8. The stop of the stop washer should not be pressed too hard to facilitate the next disassembly.

9. After the glue roller is installed, use a pointed oil gun to inject an appropriate amount of high-temperature grease from the oil-filling hole.

Install the copper components:

1. After installing the glue roller, install the upper copper components.

2. Severely worn copper components need to be replaced.

3. For copper components that can be used or repaired, only the sealing ring needs to be replaced.

Note: Pay attention to the installation order and do not damage the components.

4. The copper sleeve should be placed at the bottom of the heating tube

Check and maintain the glue roller:

1. Normally switch the glue roller.

2. Check whether the baffle of the glue roller is properly fitted: The glue roller should keep a distance of 0.1mm from the workpiece during glue-applying. It is difficult to measure during actual installation. It is mainly judged by the thickness of the remaining glue layer after the glue roller rotates over the workpiece. The greater the distance between the glue roller and the workpiece, the more durable the glue roller is. In daily life, the distance between the glue roller and the workpiece should be checked, which should not be less than 0.1mm.

3. Check the cable and glue level probe of the glue roller.

4. Regularly add qualified high-temperature grease.

5. Clean up the overflowed hot melt glue in time.

6. Check whether the advance and retreat of the glue roller are normal.

7. Regularly monitor the temperature of the glue roller.

8. Check whether the floating amount of the glue roller is appropriate

9. Check whether the airlock of the glue roller is normal.

The following is a list of Homag glue roller wearing parts:

4008410186

4400841021

2006213680

2006515351

6005-2ZR-C3

Glue pots are important parts of edgebanding machines. Maintaining the glue pot on a regular basis is crucial to the long-term life of your glue pot. Regular maintenance can help you avoid unexpected downtime and keep your edgebanding machine running optimally.

RicoCNC can offer brand new glue pots for Homag edgebanding machines and repair kits for glue pots. If you want to replace your old glue pot, rebuild it, or repair it, welcome to contact us.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665