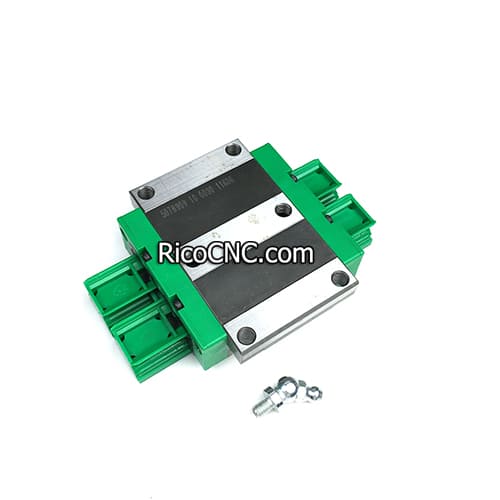

The linear guide block(linear bearing blocks, guide rail carriage, linear guide sliders, bearing trucks, linear bearings) is an important component in the linear guide system. A linear bearing block is a device that achieves linear motion through rolling, usually, the linear guide system consists of a guide rail and a linear guide slider. The linear slider is equipped with balls inside, which can provide high-precision linear motion control. In this article, we’ll talk about how linear bearing blocks work, and what's preload.

What are the linear bearing blocks?

Let’s first introduce the partner of the linear bearings.

The linear guide is the fixed part of the linear motion system, it is used for linear motion applications repeatedly. It has high torque and high load features. Moreover, it has a highly precision-machined surface to ensure low friction and high precision when contacting the linear bearing block, thereby achieving high-precision linear motion.

The linear guide block is the movable part in the linear motion system, usually consisting of a base and a movable component. The inside of linear bearings with rolling typically reduces friction with the guide rail and provides smooth movement. It usually includes two or more lines rolling.

How do the linear bearing blocks work?

The working principle of the linear guide block uses the rolling of balls between the guide rail and the linear block to transmit power. When the linear blocks are subjected to an external force, the balls roll along the straight line of the guide rail, driving the linear blocks to move in a straight line. The linear guide can provide high motion accuracy and smoothness due to the low friction.

What is the preload of the linear bearing block?

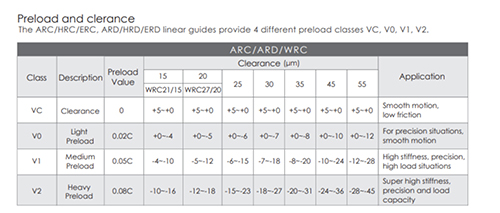

Preload of the linear guide block eliminates the gap between the linear guide and the linear rail and increases the rigidity of the linear guide and linear bearing block.

Generally, the preload of the linear bearing block is divided into no preload, medium preload, and heavy preload for every brand of linear block. The greater the preload, the better the rigidity.

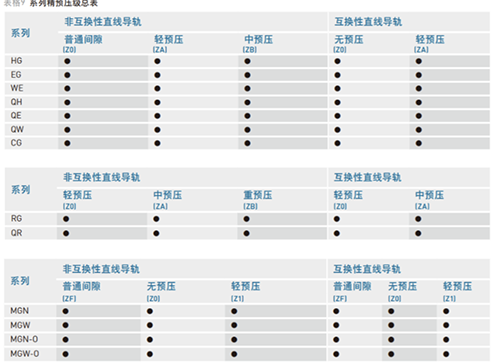

Hiwin preload grade symbols are marked as ZF, Z0, Z1, ZA, ZB, etc. Different models have different preload grades. See the below picture.

Z1 (Light Preload): This preload of the carriage is used in equipment that requires high precision but light loads.

Z2 (Medium Preload): This preload of the carriage is mainly applied in devices that demand high rigidity, such as CNC machining centers, CNC machine tools, lathes, and other machinery. RicoCNC mainly offers various brand linear blocks.

Z3 (Heavy Preload) sliders: These are used in equipment with very high rigidity requirements, like steel plate laser cutting machines.

ZF (Minimal Clearance): applied in conveyors.

Z0 (Zero Clearance): They are used in places where precision requirements are low precision and low slider resistance. For example, cutting machines, and automatic packaging machines.

RicoCNC can supply a series of linear bearing blocks, servo motors, servo drives, and other CNC spare parts. If you need them, do not hesitate to contact us.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665