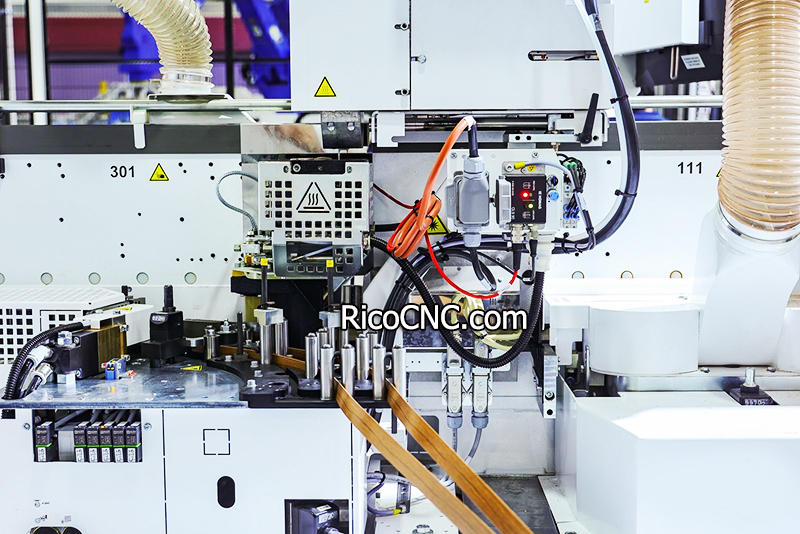

The glue pot is a crucial part of the edge banding machine. It is a container for storing and heating glue. After the hot glue melts, it is evenly sprayed to the edge of the board through the glue pot spraying device. The wood panel is edge-sealed using hot glue.

The glue pot works as follows:

Heating system: The glue pot is equipped with a heating device, usually an electric heating tube or a hot air system, which provides heat energy to melt the glue in the glue pot and turn it into hot glue. When the heating system is turned on, the heating cartridge will be heated by the heating current and generate a high temperature. This raises the temperature inside the glue pot, heating the glue inside the glue pot to the appropriate temperature, melting it, and maintaining fluidity so that it can be evenly applied to the edge of the board.

Tape feeding: The edge banding machine glue pot usually has a tape feeding system. The tape is introduced from the bottom or side of the glue pot and pulled out of the glue pot by rollers or conveyor belts. In this way, the edge banding tape passes through the heating device and is heated when passing through the heating area.

Tape melting: When the tape passes through the heating area, the adhesive on the tape melts due to the high temperature. The melted adhesive becomes liquid and sticky. This allows the tape to adhere to the edge of the workpiece in subsequent processes.

Tape application: The melted tape is transferred to the workpiece surface. During this process, the tape contacts the edge of the workpiece and the adhesive on the tape adheres to the edge of the workpiece. This forms a strong edge seal that protects the edge of the workpiece from damage.

Cooling of the tape: After edge banding, the tape needs to be cooled to allow the adhesive to solidify and set. Usually, the edge banding machine is equipped with a cooling device, such as a cold air system or cooling rollers. This will gradually solidify the adhesive and strengthen its adhesion to the edge of the workpiece.

The above is the working principle of the edge banding machine glue pot. By heating and melting the tape and adhering to the edge of the workpiece, the edge of the workpiece is sealed. By controlling the temperature, flow rate and pressure of the glue, the quality control of the edge banding and the improvement of production efficiency can be achieved.

Automatic edge bander machine with glue pot is a great machine with flexibility. It allows to glue different materials, such as HPL and some even apply wood strips.

RicoCNC can offer a list of glue pot parts and components, including seal ring, heating elements, glue roller, glue level sensor, etc. We can also supply new complete glue pots. If you need edge bander parts and accessories, welcome to contact us.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665