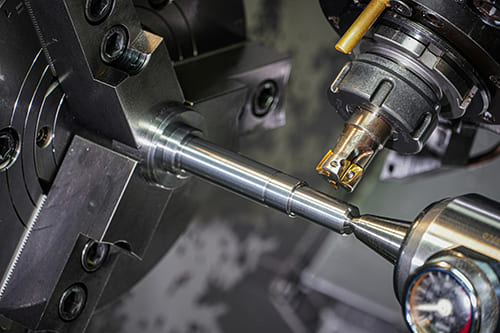

A CNC spindle is a critical component in CNC machines that performs the cutting, drilling, and milling operations. It consists of several key components that work together to ensure precise and efficient machining.

What’s the main parts for a CNC Spindle?

A CNC (Computer Numerical Control) spindle is a rotating shaft driven by a motor within a CNC machine. It holds the cutting tool (like a drill bit or milling cutter) in place and rotates it at high speeds to perform precise machining tasks on various materials, including metal, plastic, and wood.

The key role of the spindle is to ensure smooth and precise rotation, which is essential for achieving high quality machining and accurate cutting. The design and function of a CNC spindle however involves a complex system of components that work in conjunction with each other to achieve perfect results. The following is the spindle component system:

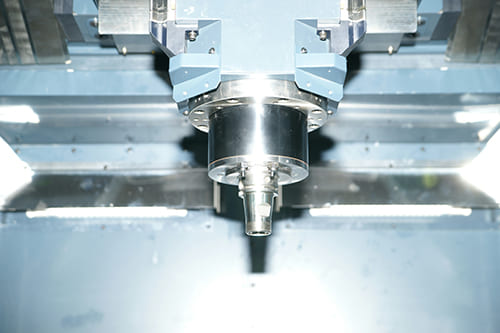

1. Spindle Motor

The spindle motor provides the power needed to rotate the spindle shaft. This motor is designed to operate at various speeds and provide the torque required to handle different cutting and drilling tasks. The quality of the spindle motor is crucial in determining the spindle's performance and longevity.

2. Spindle Shaft

This is the key part of the spindle. The shaft rotates at high speeds, and it holds the cutting tool in place. It must be at a high standard, as any misalignment or imbalance can result in vibration, affecting both the quality of the cut and the overall performance of the machine.

3. Bearings

Bearings support the spindle shaft, reducing friction and ensuring smooth rotation. They are essential for maintaining the stability of the spindle under high-speed conditions. Properly functioning bearings prevent wear and tear and increase the lifespan of the spindle. Over time, however, bearings can wear out and may need replacing to maintain the spindle’s performance. There are many brands of bearing can be supplied here, such as NSK, SKF, etc.

4. Tool Holder

The tool holder securely holds the cutting tool in place during operation. It must keep the tool steady to avoid vibration and ensure precise cuts. If your tool holder is loose or damaged, the quality of your machining could be compromised. A reliable tool holder guarantees that your tools remain fixed and aligned, making the entire machining process more efficient. Rico supplies various standard tool holder.

5. Cooling System

A CNC spindle generates heat during operation, particularly when cutting through dense materials. The cooling system manages this heat to prevent thermal distortion, which can lead to premature tool wear or damage to the spindle itself. Efficient cooling is vital in extending the lifespan of your spindle and ensuring high-quality machining results.

By working together, these components enable precise and efficient machining of various materials.

How Does a CNC Spindle Work?

The combination of mechanical power, precision engineering and effective cooling by these spindle component systems above work together to make the spindle work smoothly.

The spindle motor is activated when the CNC machine is started. The spindle motor starts rotating the spindle shaft with the desired speed according to the current operation.

The cutting tool is held by the tool holder, engages the material. The high speed rotation enables the tool to make precise cuts or drill holes. Throughout the process, bearings ensure that the spindle shaft remains stable and rotates smoothly. This minimizes vibration, which is essential to ensure precise cutting and maintain material quality.

When the spindle is running, friction and cutting forces generate heat. The cooling system manages this heat and ensures that the spindle remains within the operating temperature range. This prevents problems such as thermal distortion, which could otherwise lead to deformation of the spindle or the material being processed.

If you’re ready to upgrade your CNC spindle or need reliable replacement parts, don’t hesitate to contact us. At Suzhou Rico Machinery Co. Ltd., we pride ourselves on offering quality products and exceptional customer service.

Visit our website to learn more about our CNC spindles and related accessories. Reach out to us today to send an inquiry or get more details on how we can help improve your machining operations

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665