The CNC Gripper is a key part of industrial automation, used in CNC machines, assembly lines, and robotic operations. It boosts productivity, accuracy, and automation by gripping, holding, and moving workpieces precisely. But over time, its performance can drop, leading to Gripper Performance Issues like unstable gripping, slow response, more wear, and misalignment. These performance problems hurt production efficiency, product quality, and equipment lifespan.

In this article, we’ll explore the top Causes of Gripper Failure and provide practical solutions to help you address Gripper Performance Decline. Learn how to fix CNC Gripper issues and keep your automation systems running smoothly.

Common Causes of Gripper Performance Decline

1. Mechanical Wear

Over time, the constant use of CNC Grippers can cause material fatigue and wear on parts like clamping jaws, bearings, and guides. This wear and tear can easily lead to a drop in performance, contributing to Gripper Performance Issues.

2. Poor Lubrication

Inadequate lubrication or contaminated lubricant can significantly affect the performance of CNC Grippers, resulting in increased friction, component wear, sluggish movement, and even overheating damage. Contaminated lubricants may also introduce impurities that cause clogging or corrosion, further reducing accuracy and lifespan.

3. Electrical System Failures

If the motor gets old or is pushed too hard, the CNC Gripper might lose power, respond slower, or even stop working altogether. Sensor failures or circuit issues can also lead to positioning errors or unpredictable movements, worsening Gripper Performance Decline.

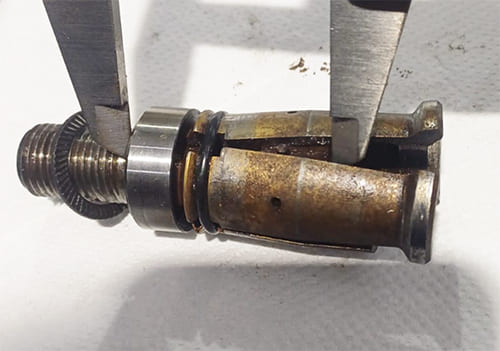

4. Pneumatic/Hydraulic System Issues

Low pressure, leaks, clogged lines, or worn-out seals can cause performance problems in CNC Grippers, such as weak grip, slow movements, or total breakdowns. These issues can also damage other parts of the system.

5. Environmental Factors

High temperatures, humidity, dust, and corrosive environments can damage CNC Gripper materials, leading to deformation, rust, wear, or corrosion. These factors significantly impact accuracy, stability, and lifespan, contributing to Gripper Performance Issues.

6. Improper Use

Overloading or incorrect operation can cause Causes of Gripper Failure, such as component wear, loss of accuracy, or even system failure. Proper training and adherence to operational guidelines are essential to avoid these performance problems.

7. Design Flaws

Improper material selection or structural design, as well as compatibility issues, can lead to Gripper Performance Decline, resulting in weak grip, excessive wear, or poor movement. Addressing these flaws is key to improving performance.

8. Control System Issues

Software malfunctions, improper parameter settings, or signal interference can cause CNC Gripper control failures, leading to inaccurate actions or delayed responses. These issues are common Causes of Gripper Failure.

9. Natural Aging

Deterioration of non-metallic parts and worn or peeling surface coatings can affect the performance of CNC Grippers, leading to Gripper Performance Decline over time.

10. External Impact or Vibration

Mechanical shock, unstable installation, or vibration can cause structural damage, loss of precision, or loosening of parts, significantly impacting CNC Gripper performance and lifespan.

How to Fix CNC Gripper Issues

These performance problems can cause unstable gripping, slow movements, loss of precision, or even system failures, hurting productivity and equipment lifespan. To address Gripper Performance Decline, follow these steps:

1.Perform regular CNC Gripper maintenance to inspect and replace worn parts.

2.Optimize designs and materials to prevent Causes of Gripper Failure.

3.Ensure system compatibility and proper installation.

4.Set parameters correctly to avoid control system issues.

5.Reduce shocks and vibrations to protect the CNC Gripper from external impacts.

6.Prevent signal interference to maintain accurate control.

7.Monitor the system in real-time to detect and resolve Gripper Performance Issues early.

By implementing these solutions, you can boost the reliability, accuracy, and stability of your CNC Gripper, ensuring it runs smoothly and extends its service life.

Is your CNC Gripper experiencing performance problems or showing signs of Gripper Performance Decline? Don’t let these issues slow down your production! At Rico CNC, we specialize in CNC Gripper maintenance and upgrades to restore peak performance and extend the lifespan of your equipment.

Contact us today to learn more about our CNC Gripper update services and how we can help you fix Gripper Performance Issues efficiently. Let’s keep your automation systems running smoothly and reliably!

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665