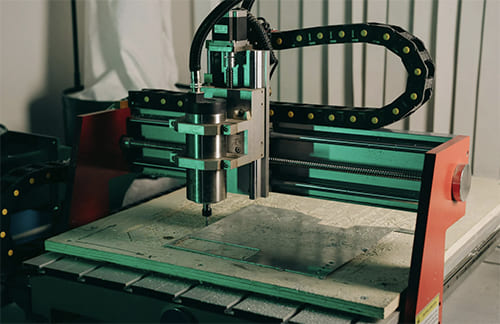

In industrial production or mechanical equipment, the CNC gripper, as the key components, directly affect the operational efficiency and safety of the equipment. However, as the use of time increases, the CNC grips will inevitably be damaged. So, how to determine whether the CNC grips need to be replaced? This article will reveal 5 common signs to help you detect the problems in time and avoid production accidents or equipment damage caused by CNC grips failure.

5 Key Signals for Replacing a CNC gripper

Knowing when to replace a CNC gripper is crucial for maintaining equipment efficiency and safety. Below are the 5 most common signs of gripper failure that indicate it’s time for a replacement. These signals are widely recognized in industrial and mechanical applications, helping users avoid unexpected downtime and costly repairs.

1. Significant Loss of the Gripping Force

A critical warning sign is reduced gripping capacity, manifested by objects slipping during operation or requiring excessive force to secure loads. Industry studies reveal that a 20% loss of gripping power can lead to 5-15% reductions in production efficiency in material handling applications.

Recommend to do Regular gripping force test with calibrated equipment, this problem often will be caused by the worn piston seals or damaged hydraulic components.

2. Cracks or deformations on the surface of the pulling grips

Another critical signal for CNC gripper replacement is the presence of visible cracks, deformation, or excessive wear on the gripper’s surface. Cracks, deformations, or excessive wear exceeding design tolerances (e.g., cracks>2mm or dimensional deviations > ±0.05mm) signal material fatigue or overload.

Consider using high-tech tools like industrial endoscopes or 3D laser scans For pinpoint evaluation, . If you spot tiny cracks around stress hot spots—like near weld lines—stop everything right away. This usually happens when the equipment is overloaded or hasn’t had enough breaks to relieve pressure.

3. Unusual Noises During Operation

Abnormal noises (e.g., grinding, metallic clashing) during operation indicate internal component wear. These abnormal sounds often point to issues like misaligned components, worn-out parts, or insufficient lubrication.

Key areas to inspect include:

• Rolling bearings (lack of lubrication causes 200–500 Hz frequency anomalies)

• Linear guide rails (metal debris generates sharp scraping sounds)

• Motor current fluctuations (high-frequency hum indicates torque deficiency)

4. Frequent Malfunctions or Failure to Operate

If your CNC grippers are constantly jamming, gripping, or failing to perform their intended task, it's a clear sign of a serious decline in performance.

Implement a fault logging system to track:

• Frequency of failures (daily/monthly)

• Time of reset

• Type of load during failures

When a gripper begins to fail frequently, it is no longer reliable and should be replaced immediately.

5. Failed Safety Inspections or Exceeded Service Life

Periodic safety inspections are critical in determining the need for clamp replacement.

Manufacturers provide ISO 10816-based life cycle guidelines:

Light-duty CNC grippers: 3,000–5,000 cycles

Heavy-duty CNC grippers: 10,000–15,000 cycles

Adhering to the manufacturer's service life guidelines and performing routine inspections can help you determine the right time to replace your grippers to ensure safety and reliability.

Don’t wait for a CNC gripper failure to disrupt your operations! Regularly inspect your CNC grippers or clamps for these 5 key signals—loss of gripping force, visible cracks, unusual noises, frequent malfunctions, and failed safety checks. By staying proactive, you can avoid costly downtime, ensure workplace safety, and keep your equipment running smoothly.

Need help choosing the right replacement CNC gripper or scheduling maintenance?Contact our experts today for personalized advice and solutions tailored to your needs. Rico supply various CNC grippers with many brands, such as Riken Seik, Acrow, Royal, Chumpower, Bright, OTT, etc.

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665