In the field of woodworking machinery, Laguna Tools edge banding machines are well known for their excellent performance and reliability. Whether it is a small woodworking workshop or a large furniture manufacturer, Laguna edgebander can provide efficient edge banding solutions. This article will take a deep look at the product range of Laguna edge banding machines and their common accessories to help you better understand how to improve the performance and efficiency of the edge banders by using these accessories.

Introduction to Laguna edgebander machine range

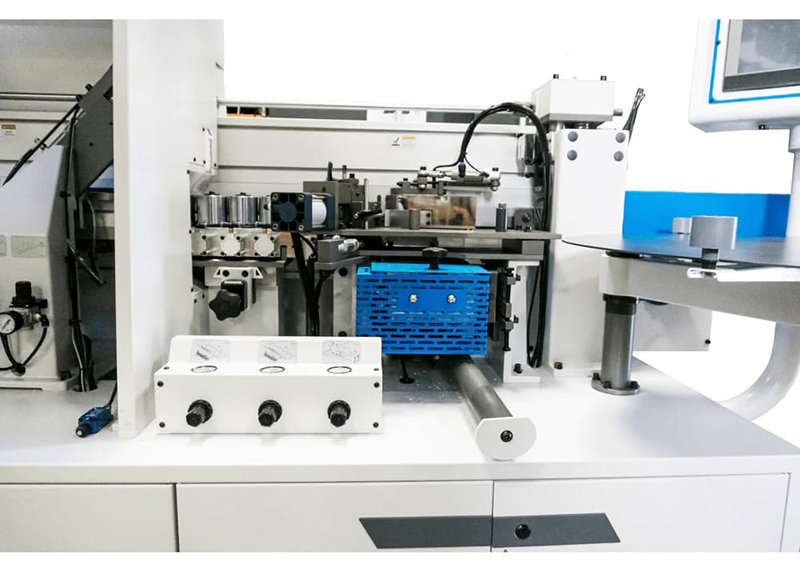

The Laguna edgebander series covers a variety of models suitable for different production needs. The following are the main product ranges of Laguna edge banding machines:

1. Laguna Bandit 3/2 Edgebanders

The Laguna Tools Bandit 3/2 is the compact heavyweight in the line of automatic edge banders. Designed for everyday professional use with all 2mm materials. The gluepot allows maximum flexibility with PVC, wood tape, laminate, and wood strips. Standard features include automatic end trim with dual blade end cutting units, edge trimming with dual high-frequency motors, buffing unit, adjustable overhead control panel, pull-out support rollers for wide panels, and electronic temperature control with digital readout.

2. Laguna Edgebanders Bandit 4

The Bandit 4 is perfect for cabinet shops that are doing thin edgebanding from 0.4-3mm products. This machine features top/bottom and front/rear edge scraping and buffing. The Bandit 4 also has a swiveling control cabinet that enables the operator to control the machine during both job setup and while edgebanding material.

3. Laguna Edgebanders Bandit 5

The Bandit 5 is the flagship model of the edgebander line. With the addition of Pre Milling and Corner Rounding, this machine has all the features you’ve come to expect from a Laguna Edgebander. The Bandit 5 can apply a perfect edge finish for every time.

More and more customers are choosing Laguna edgebanders because of their excellent value for money. Edgebanders are essential tools in any woodworking workshop. However, to get the most out of these high-performance machines, investing in the right and high-quality accessories is key.

Here we list some essential parts for Laguna Edge Banding Machines. If you are interested in, please keep reading!

1.Chain Track pads

The size 71x48mm track pads is a chain block commonly used in Laguna edgebander machines. The chain track pad is the core component of the edge banding machine conveying system, responsible for smoothly conveying the wood panel from the feed end to the discharge end. During the conveying process, the chain pad needs to maintain a stable speed and force to ensure that the board will not deviate or shake during the edge banding process, thereby ensuring the precise fit between the edge banding strip and the wood board. The chain block often contacts and rubs against the board, and is easily worn. It is one of the commonly used consumables of the edge banding machine.

2.Pressure Wheels for Laguna Edge bander

The rubber pressure wheel applies pressure on the surface of the wood board to ensure that the board remains stable during transportation and avoids deviation or shaking, thereby ensuring the precise fit between the edge banding and the board.

3. Edgebander Trimming Cutter

a. Rough trimming cutter

The main function of the rough trimming cutter is to quickly remove the excess part of the edge banding strip, laying the foundation for the subsequent fine trimming and polishing process.

Example:

Trimming Blade for Bandit 5 edgebander Machines

Designed for rough trimming applications Φ56*Φ16*14*4Z

b. Fine Trim Cutter

The fine trim cutter is used to trim the edge of the edge banding and remove excess edge banding materials (such as PVC, ABS, or solid wood edge banding) to ensure that the joint between the edge banding and the board is smooth and burr-free, thereby improving the aesthetics and functionality of the edge banding.

Example:

Bandit 4 Edgebander Fine Trim Cutter R2

With dimensions of Φ69*Φ16*13*4Z R2,

4. PCD premilling cutter

The main function of the pre-milling cutter is to pre-process the edge of the board to ensure that the edge of the board is flat and smooth, thus providing a good foundation for the subsequent edge banding process.

Example:

125x30xH65 Z3+3 PCD premilling cutter for Laguna Bandit 4 with premill

5. End Trim Belt

The edge banding machine belt connects the motor and the conveying system, transmits the power of the motor to the conveying system, drives the conveyor chain or rollers, and ensures that the plate moves smoothly during the edge banding process.

Example:

End Trim Belt T5 500 x 10 for Edgebander Bandit 3/2

BELT 730 X 3/4 for Edgebander Bandit 3/2

6. Edgebander End Trim Saw Blade

The main function of the saw blade is to cut off the excess part of the edge banding to ensure that the joint between the edge banding and the board is flat and smooth, thereby improving the aesthetics and functionality of the edge banding.

7. Buffer Pads

During the operation of the edge banding machine, the buffer pad (also known as the polishing brush or polishing wheel) is a vital accessory, which plays a key role in the final processing stage of the edge banding. The main function of the buffer pad is to polish the edge of the edge banding strip to ensure that the edge of the edge banding strip is smooth and burr-free.

Example:

150X55X20 Buffer Pads for Bandit 3/2 Edgebanders

Edge banding machine accessories play an irreplaceable role in the edge banding process, directly affecting the edge banding quality, production efficiency, and equipment life. By choosing the right parts and maintaining them regularly, the operating efficiency and edge banding quality of the edge banding machine can be significantly improved.

RicoCNC provides you with a range of high-quality Laguna Tools edge banding machine accessories. Whether you are a small woodworking workshop or a large furniture manufacturer, our accessories can meet your needs, helping you improve edge banding quality, increase production efficiency, and extend machine life.

Visit RicoCNC.com now to explore our range of Laguna Tools edge banding machine parts and choose the most suitable accessories for your edgebander!

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665