Edgebander machine is an important equipment in woodworking machinery, mainly used for edge banding of boards (such as furniture boards, cabinet boards, etc.). Edgebanding machine makes the edge of the board more beautiful and durable by bonding edge banding strips (such as PVC, ABS, solid wood, etc.) to the edge of the wooden board, and prevents moisture penetration and edge wear, thereby extending the service life of furniture such as cabinets and wardrobes, and reducing the release of formaldehyde.

The advantages of an edge banding machines make them widely used in furniture manufacturing, cabinet production, decorative material processing and other fields, greatly improving production efficiency and saving labor costs.

Edgebanding machines usually have processes such as conveying, gluing and edging, cutting, front and back end trimming, upper and lower trimming, upper and lower fine trimming, upper and lower scraping, and polishing, which can achieve edge banding of different lengths, thicknesses and materials.

There are different types of edgebander machines on the market. According to the level of automation, functions and application scenarios, edge banding machines can be divided into the following 9 types:

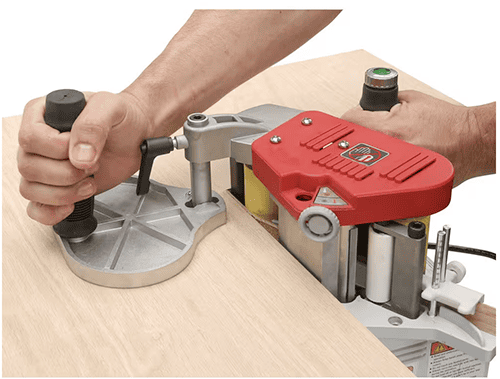

1. Portable handheld edge banding machine

This edge banding machine is small and lightweight, a portable device suitable for on-site construction or small-scale production, usually hand-held by the operator, suitable for smaller edge banding tasks or work in narrow spaces. This machine is usually suitable for small-batch production or repair job, and can handle straight and curved edges.

2. Manual edgebander machine

The manual edgebander machine is simple to operate, relying on manual feeding, gluing and pressing, with a simple structure and low price, suitable for small woodworking workshops or DIY enthusiasts. Its characteristics are low investment, but it requires high proficiency of operators, and the edge banding quality may not be as stable as that of automatic edgebanding machine.

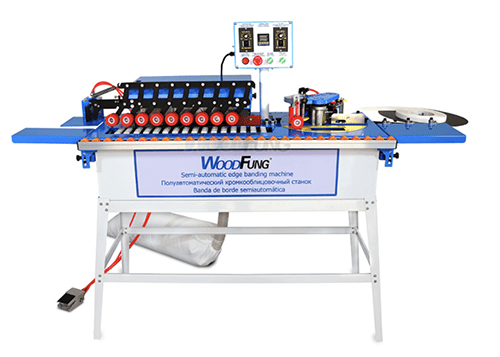

3. Semi-automatic edgebanding machine

Combines manual and automatic functions, and some processes are completed automatically by the machine, which is suitable for small and medium-sized furniture manufacturers.

, relatively simple to operate and relatively cheap. High production efficiency and stable edge banding quality. However, manual intervention is still required and the level of automation is limited

4. Fully automatic edge banding machine (CNC edgebanding machine)

Fully automatic edge banding machine has multiple functions such as pre-milling, gluing, edge banding, trimming, finishing, scraping, polishing, etc. It can realize automatic operation, high production efficiency and stable edge banding quality. It is suitable for linear edge banding and trimming of various materials such as medium density fiberboard, blockboard, solid wood board, particleboard, etc. It is suitable for large furniture manufacturers and cabinet manufacturers. Now many panel furniture factory use fully automatic edge banding machines to improve efficiency and edge banding quality.

5. Linear edge banding machine

Linear edge banding machine is mainly used for edge banding of straight edges, suitable for edge banding of straight edges such as furniture boards and cabinet boards. It is relatively simple to operate, fast, and high-precision, and is suitable for large-scale standardized production.

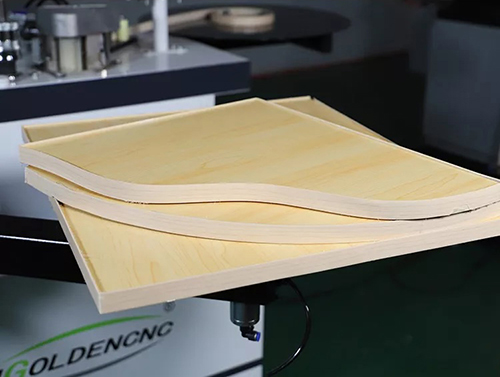

6. Curved edge banding machine (special-shaped edge banding machine)

Special-shaped edge banding machines can process irregular edges such as curves and arcs. They are suitable for edge banding of curved edges of special-shaped furniture boards, decorative materials, etc. They adapt to curves through flexible pressure wheels or CNC systems. They are suitable for producing high-end furniture or products that require complex edge processing.

7. Hot glue edgebander machine

The hot glue edge banding is bonded by heating and melting the adhesive strip (EVA or PUR adhesive).

a. EVA edge banding machine

Uses ethylene-vinyl acetate copolymer (EVA) hot melt adhesive, which has a lower cost but poor temperature resistance (about below 60°C) but relatively poor durability and aesthetics.

b. PUR edge banding machine

Uses moisture-curing reactive polyurethane hot melt adhesive (PUR), which has high bonding strength and high temperature resistance (up to 120°C), suitable for high-end furniture. The edge banding effect is better and durable, suitable for high-end furniture production

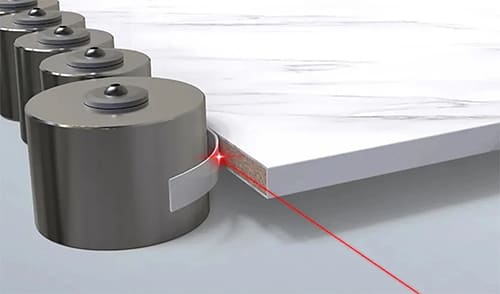

8. Laser Edge Banding Machine

Laser technology is used to activate the pre-applied glue on the edge banding to achieve seamless bonding. The edge banding effect is beautiful and environmentally friendly, with no glue lines, excellent waterproofness, and smooth edges. It is a high-end model. The equipment cost is relatively high. It is mainly used for high-end cabinets and bathroom furniture.

9. Hot air edge banding machine

Hot air edge banding machine is to spray high temperature and high pressure hot air onto the edge banding tape through the edge banding machine nozzle to melt the pre-coated glue layer or functional layer, and then use the pressing wheel mechanism to press the edge banding tape onto the panel. No glue tank or liquid glue is required, which is clean and efficient.

Edge banding machines play an important role in the modern woodworking industry and are an indispensable equipment in the production process.

When choosing an edge banding machine, you need to decide on the appropriate type based on production needs, budget and the characteristics of the processed material. Choosing the right edge banding machine can improve production efficiency, improve product quality and reduce production costs.

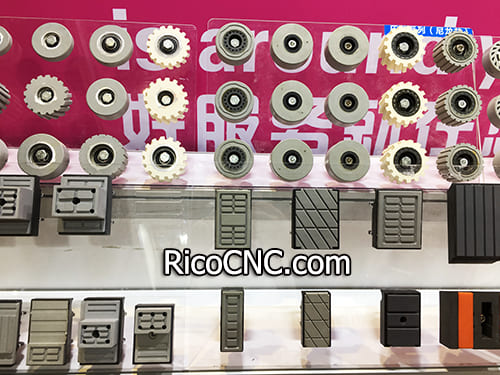

The stability of the edge banding machine not only depends on the main machine, 30% of the failures are caused by aging accessories! Problems such as rubber pressure wheel wear, track pads wear and trimming cutters blunting will directly lead to edge blistering or uneven glue lines. Choosing high-precision compatible accessories can extend the life of the machine and reduce downtime.

RicoCNC can provide a range of edge banding machine parts, 48 hours global direct delivery, and free technical adaptation consultation.

If you have any needs, Welcome to contact us!

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665