Struggling to find the right motor for your HAAS machine? Don't worry! We've put together a list of Yaskawa motor models commonly used in HAAS machines for you to choose from.

93-0346 MOTOR, SERVO SIGMA-1 09 (SHORT) YASKAWA Servo Motor SGMG-09A2AB

93-1923 MOTOR,SERVO SIGMA-5 YASKAWA 13 - LIVE TOOL USE 93-1918 SGMGV-13ADA61

93-0347 - MOTOR, SERVO SIGMA-1 YASKAWA 13 SGMG-13A2AB

93-1761 - MOTOR, SERVO YASKAWA 09 NO/BRAKE W/SEAL

93-1922 - MOTOR, SERVO SIGMA-5 YASKAWA 09 SGMGV-09ADA61 SGMGV-09ADA-HA11

93-1924 - MOTOR, SERVO SIGMA-5 YASKAWA 20 SGMGV-20ADA61

93-2711 - MOTOR, SERVO SIGMA-5 YASKAWA 08

93-2714 - MOTOR, SERVO SIGMA-5 YASKAWA 04

93-3416 - MOTOR, SERVO SIGMA-7 YASKAWA 04

93-62-0013 - MOTOR, SERVO SIGMA-1 YASKAWA 09 (LONG)

etc.

How to replace these motor from the HAAS CNC machines?

1. Safety Precautions

Always power off the machine and disconnect energy sources before starting. Wear safety gloves and goggles.

2. Tools & Materials Needed

Putty knife

Acetone & clean cloth

Dielectric grease

Torque wrench (refer to HAAS Fastener Torque Specs)

Replacement servo motor & coupler access gasket

3. Removing the Servo Motor

Step 1: Clear Access to the Motor

Power Down: Turn off the machine completely.

Remove Obstructions:

Axis Component to Remove Location

Y-Axis Back column enclosure Rear of the machine

X-Axis Saddle’s left waycover Left side of the saddle

Step 2: Expose the Coupler

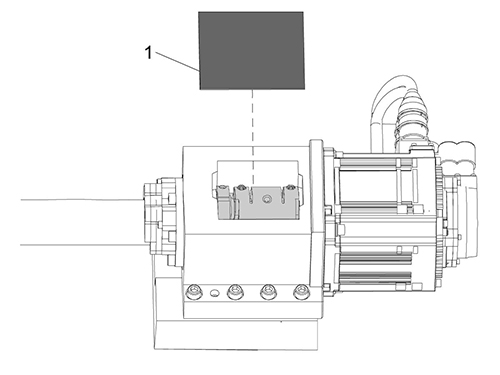

Peel back the coupler access gasket [1] using a putty knife if stuck.

Step 3: Disconnect the Motor

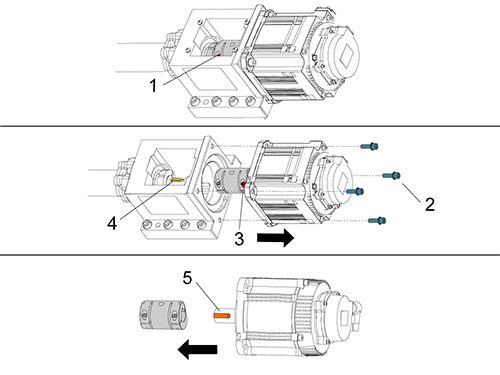

Loosen the lower coupler clamping bolt [1].

Disconnect the power cable, noting its orientation.

Remove the motor mounting bolts [2].

Pull the motor straight out to disengage it from the ballscrew.

Step 4: Remove the Coupler

Loosen the upper coupler clamping bolt [3] and detach the coupler.

4. Installing the New Servo Motor

Step 1: Prepare the Coupler & Shaft

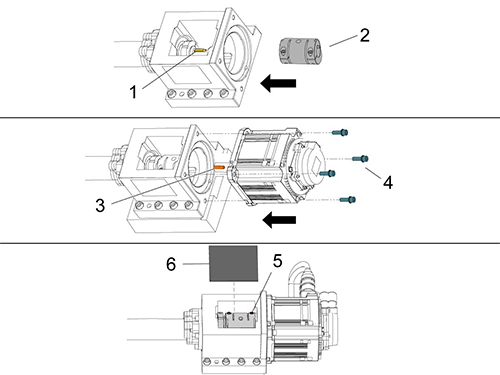

Key Alignment: Ensure the shaft key is installed on the ballscrew ([1]).

Hand-rotate the new motor shaft to match the old motor’s orientation.

Step 2: Attach the Coupler

Slide the coupler onto the ballscrew ([2]).

Note: Keep clamping bolts loose temporarily.

Step 3: Mount the Motor

Align the motor shaft key ([3]) with the coupler’s keyway.

Push the motor into the housing and secure with mounting bolts [4].

Torque bolts to HAAS specifications.

Step 4: Secure the Coupler

Center the coupler ([5]) between the motor and ballscrew.

Torque both clamping bolts [5] to spec.

Step 5: Reapply the Gasket

Clean the housing surface with acetone.

Apply a new coupler access gasket [6].

5. Critical Installation Tips

Dielectric Grease: Apply sparingly only to connector contact points.

Cable Connections:

Power Cable: Align the amphenol key slot and twist to secure.

Encoder Cable: Match arrows, push until locked, then gently tug to confirm.

Home Sensor: Align and twist to secure.

Rico can supply YASKAWA servo motors for HAAS CNC machine, so if you have the HAAS part number (YASKAWA servo motor model number will be better), we can supply the best price for you. Please contact us for more information!

Tel:+86-51268235075

Fax :+86-51268235075

Mobile:+86-13390848665

E-mail: cncsale@ricocnc.com

Skype: ccsalce

Whatsapp: +86-13390848665